PLC Arduino and Raspberry Pi Panel PC for Automotive production line

An automotive production line system capable to be adapted to different needs.

Arduino and Raspberry Pi for industrial automation

This project is designed to make an automotive production line system capable to be adapted to different needs.

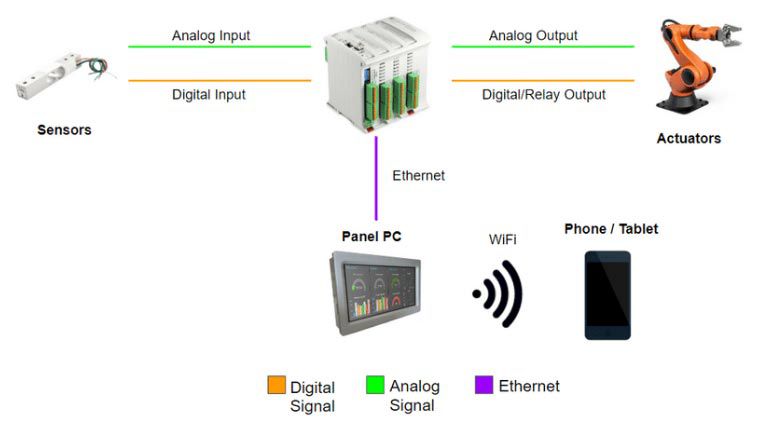

The production line will be automated using an Arduino PLC that wiil control all the processes and the robots behaviours, and a Panel PC will be able to monitorize them and to become the management point of the input-output data feed.

This application could be applied remotely using an Ethernet PLC if it is necessary and the information can be accessed wherever you want, through a VPN connected to our MQTT server.

This database could be shown on a Panel PC based on Rasberry Pi that will monitor all the information.

Control with Industrial Arduino

All the important production line data will be collected using several sensors; for example, load cells to weigh certain pieces, lasers to measure distances, pressure devices to measure the force applied assembling the pieces, etc. All this information will be sent to an Arduino PLC, where it will be processed and, considering the specific orders previously programmed or the ones introduced through the Panel PC, the Industrial Arduino PLC may send the commands to the production line actuators such as all the mechanized arms and the robots to execute all the orders.

All this information can be monitorized through the Panel PC, where you can control and configure all the system parameters.

In the Panel PC there will be also a broker server (MQTT) that is responsible for receiving and sending data between the Arduino PLC and the Panel PC.

To monitor the data, Node-Red will be used.

Industrial Panel PC based on Raspberry Pi

Industral Controller based on Arduino

Objective

The main points to achieve are the following:

Conclusions

PLC Arduino for Industrial Automotive

The automotive production line will be fully automated, instead of the specific control parameters that have to be set. All the important data could be collected through all kind of sensors, like the ones said previously.

This information will be sent to an Ethernet PLC which will be previously programmed to process all the input data and manage the output orders to the actuators in a certain way.

When the input data will be in the PLC Arduino, it will send it to the Panel PC using Ethernet and you could monitorize it. Like we said, there could be specific orders previously saved inside the PLC or we can change and manage this control with the Panel PC too.

All this Panel PC actions could be done through another device such as a cell phone or a tablet because of the WiFi connection between this and the panel. To monitor all the data and to stablish this connections with a phone/tablet, Node-Red will be used and a server has to be created and configured.

Once all the orders are introduced to the system, they will be sent to the actuators in the line machinery (robots, mechanized arms, etc.).

All the input and output data could be digital or analog, always taking into account the available i/o in our devices.

The actuators will execute the orders and you can monitorize and manage everything through the Panel PC, the phone or the tablet. This system could be applied to different production lines and adapted to different changes.

Do you want to receive more information about Automotive Automation?

Open Source technology allows you to develop your Monitor applications.

Just fill the form and we will send you several examples about how to use Open Source based devices on your projects.