Warehouse automation with PLC Arduino and Touchberry Screen

The solution requests stored products and sends them to their corresponding line at the loading docks

Industrial Arduino for automated warehouse

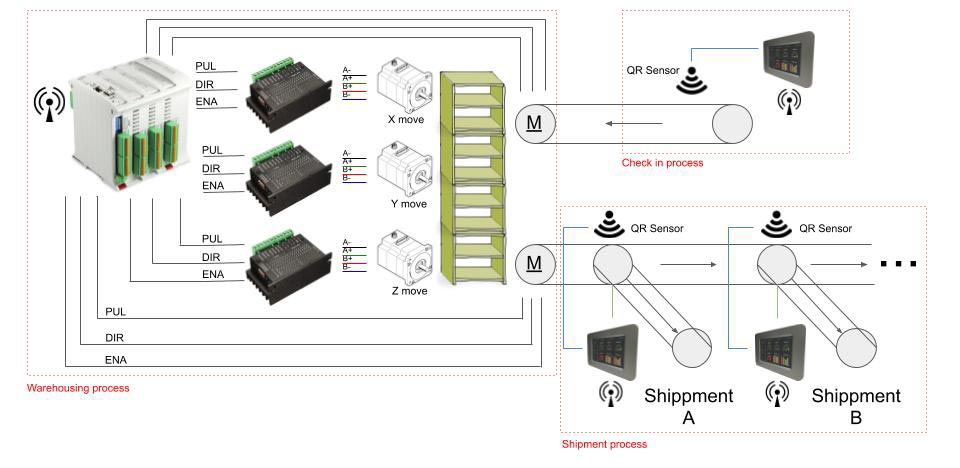

In this Arduino project for industrial automation, a warehouse will be automated with industrial controllers to store boxes of different weights in a group of shelves. The solution will be able to request stored products and send them to their corresponding line at the loading docks as well.

To have a good traceability process, a tracking system will also be implemented using QR codes. This will let the user know, at all times, the state of the warehouse. Touchberry touch screens will be used to display the package information and inform the operator that is receiving the goods as necessary.

This system will be remotely manageable thanks to a server that will connect every process via WiFi.d.

Summary

The boxes enter into the system by reading the QR code that identifies them. The application weights the parcel and stores it in the warehouse, placing the heaviest boxes at the bottom of the shelf. Once a box is requested at a loading bay, the application searches on the warehouse and positions the parcel on the shipping conveyor. When a package for a specific dock is detected, it is moved to the conveyor in its own area.

Goals

The requests of this system are as follows:

- Automated storage of a stock of boxes.

- Performing and recording the tracking of each package.

- Optimizing the energy consumed by raising loads.

- Operating at several shipping docks.

- Remotely managing the state of the warehouse.

A single PLC controller Arduino will take care of the engine management.

We will also have PC Panels in the shipping area and in every loading dock for information and management of the tasks to do.

Conclusion (hardware)

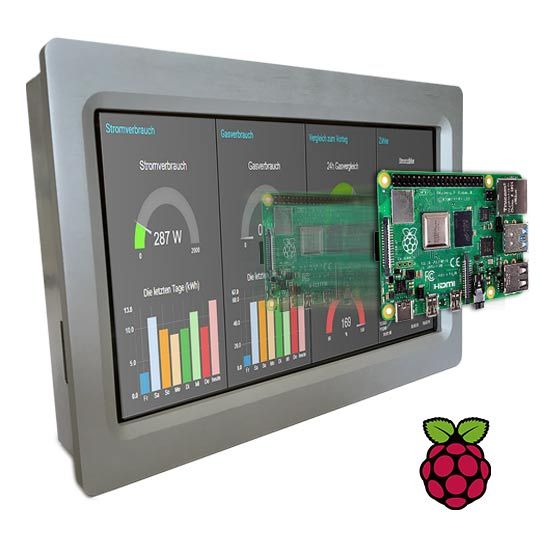

The information will be entered through a Touchberry screen, which allows the connection of a QR code reader and provides WiFi connectivity.

Once a new box is detected in the system, the industrial Arduino (an industrial PLC called M-DUINO) will turn on the conveyor through a drive. When the box reaches the warehouse location, a system consisting of three servomotors will act on the package.

The system will weigh the load by an extensiometric gause and will be able to sort the heaviest loads in an ascending order, optimizing the energetic resources and improving the structural load in the warehouse.

After requesting a package from a Touchberry screen or directly from an external server, a PLC Arduino will send the collection of the parcel, bring it to the conveyor, and divert it to its area by a QR reader. This will happen when the shipping dock screen detects that the box is directed to its position.

Check the products of this case study

Industrial Arduino PLC and HMI Raspberry Pi

Do you want to receive more information about Industrial Automation?

Open Source technology allows you to develop your Monitor applications.

Just fill the form and we will send you several examples about how to use Open Source based devices on your projects.