What is a PLC and how does it work?

A PLC or programmable logic controller is a programmable electronic device that is used for industrial automation.

These devices are basically in charge of processing data, as if it was the brain of electronics, in order to process information and be able to carry out specific activities.

In this way, for example, we could connect a sensor. Then, we can program that, if the value of this sensor exceeds X value, we could trigger an alarm connected to the outputs of the PLC, that would be activated at that moment.

PLCs are made up of a central processing unit (CPU), memory, inputs and outputs:

- The CPU is used to run the control software.

- The memory is used to store control programs and process data.

- And the inputs and outputs are used to connect the PLC to external control devices, such as sensors and actuators, and to receive and send process data.

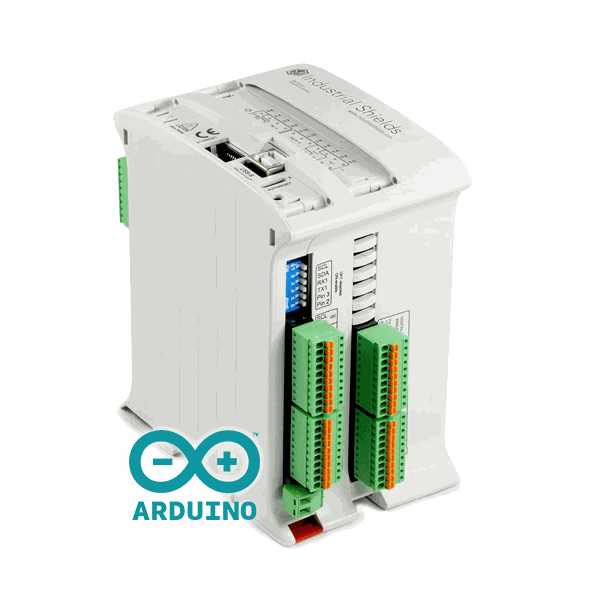

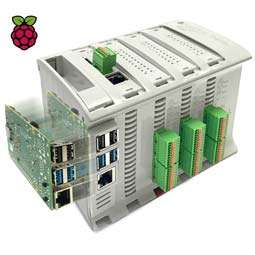

At Industrial Shields, the PLCs have different CPU:

There are countless applications that PLCs can serve that they are used in a wide variety of industries. The following applications are the most noteworthy.

Industrial Applications

Automatic Filling System for Bottles or Liquids.

Paper industries for the manufacturing of books, newspapers, and other printed materials.

Using the sensors as input to the PLC system, control the temperature or humidity.

Glass Industries for manufacturing glass and keeping records.

System for packaging and labeling food and beverages.

Power Station

The Smart Grid System monitors and detects fault situations using PLC.

Water level sensing and data collection employ real-time PLC technology.

In an automation power plant for oil and gas, a PLC is required for tasks like oil filtering, flame safety checks, pilot light on or off, and valve switching for fuel switchover.

The Auto Assembly Line System is a tool that PLC may utilize in the Power Substation.

Some Electrical Equipment (like Circuit Breaker Tripping, Capacitor Switching) can be automatically operated with PLC.

Commercial

Intelligent Traffic Signal Control System.

Automated system for handling machines.

Well drainage system automation system.

Applications of Pressure Controller in Multi-Motor Pumps.

Line Detection and Remote Control System for Mining Equipment.

Domestic

System for Controlling Water Tank Level.

Parking and car-washing system.

Controlling system for flashing lights.

System for opening and closing automatic doors.

Remote monitoring software for fans and air conditioners.

Discover more sectors with this top 50 industrial applications

If you want to start programming the PLCs, you can start with:

For any other information, please Contact us >>>

What is a PLC and how does it work?