Why?

Because we needed something different for our professional projects.

The lack of flexibility when using some of the current programmable logic controllers of the market, maked us to start looking for a solution.

We met Arduino and we started to play with some basics instructions, control, data acquisition... Then we started to test, develop, and finally we created our first product:

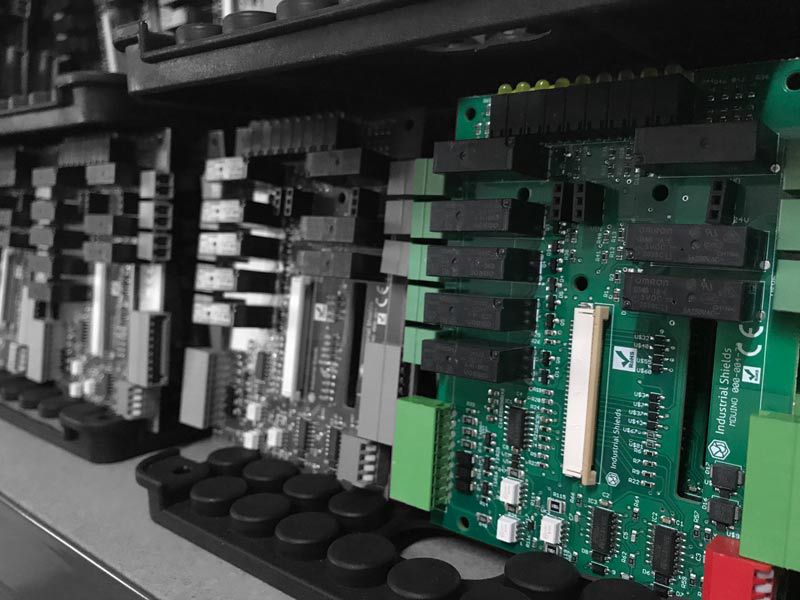

- The Arduino based Industrial PLC.

The lack of flexibility when using some of the current programmable logic controllers of the market, maked us to start looking for a solution.

We met Arduino and we started to play with some basics instructions, control, data acquisition... Then we started to test, develop, and finally we created our first product:

- The Arduino based Industrial PLC.

This development was carried out between 2012 and 2014, and since then our product range has been growing, being certificated and present in thousands of machines, installations and all kind of solutions.

When our product portfolio was stable and our products were already present in some countries, and in all kind of types and sizes of customers, we started to develop a range of products that are currently co-founded by the Horizon 2020 programme of the European Union.

Take a look at the Arduino, Raspberry and ESP32 industrial PLC range.

Industrial PLC >>

How?

Developing with a clear focus

We developed always with the goal of creating an industrial PLC.In accordance with our experience, the industrial standards and also the industrial needs, we created different boards. Those boards were designed, and then produced, using always industrial components.

One of the critical boards in industrial environments is the power supply board. Thanks to this board, the PLC can work in most of the applications and installations that our customers need.

When talking about machines, motors or installations, it is obvious that there are always special requirements that force a superior protection of the PLC.

We will arrive there too, for sure, but this product range will require a special development to work in all kinds of environments that some industries require, from ATEX to IP67 to extra protection for the electromagnetic noise, etc.

Critical elements

Another critical board is the one in charge of the communications.We started with the board for the Ardbox range, using an Arduino Leonardo board.

For the M-Duino range, we are using the Arduino Mega with which we can use Ethernet, a common requirement in industry.

The next development was the relay board to cover all the solutions that needed this.

During 2019 we have been adding GPRS and WiFi-Bluetooth but as an accessory integrated in our shield.

In 2020 we created a new whole range of Raspberry Pi PLC and adding also the LoRa range to our portfolio.

Late in 2020 and starting 2021 we developed an industrial PLC range with the ESP32 board.

Standarization

The PLC shield was also a standard box currently in the market in order to facilitate integration, installation and industrialization.We use plastic that does not melt, shields can be mounted using a DIN rail, PLCs use industrial connectors, all focused to the industrial requirements.

Both, Ardbox / M-Duino share the same box, with middle modules that allow the increasing of inputs and outputs.

We have been also developing some solutions for customers who require special products.

We are always opened to listen the needs of our customers and start a collaboration to create special products with special requirements.

Certificate.

Assuring Quality and Security

Once the PLC development was correct and reliable to start working, we started the certification process.

We ran some laboratory tests where they made work the PLC trying to find the working temperature ranges, the electromagnetic protection, etc.

Late In 2019 the first batch with the ETL certification flew to an important customer of the United States who bought some hundreds of units of the M-Duino 58.

Do you need more information?

Tell us what do you expect, what more do you need to know, and we will try to solve all your questions.

Please, fill the form below, send us an email at [email protected], or call us at +34 938 760 191