Revolutionizing Automotive Production:

The Power of Collaborative Robots

Discover how to Enhance Productivity and Streamline Operations with an ESP32 PLC

Discover More >>

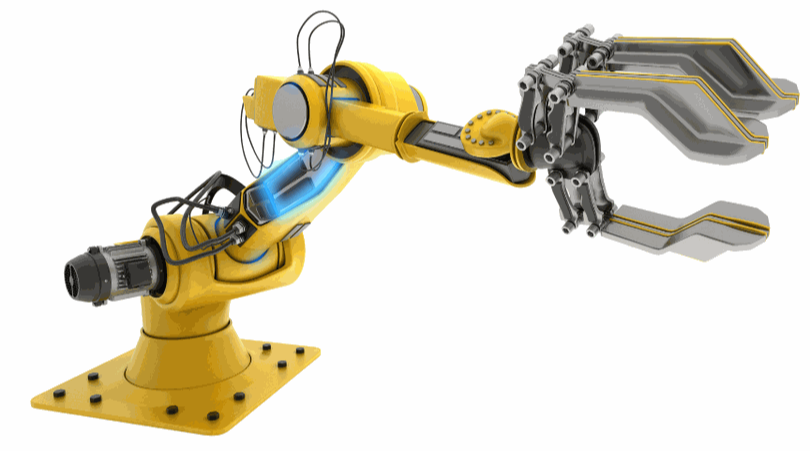

Collaborative robot for the automotive sector

In this case study, a component manufacturer, whose main customer is a direct supplier to an automotive assembly plant, seeks to increase efficiency and reduce downtime on its production lines.

To achieve this, they have decided to invest in collaborative robots (cobots) that will work alongside the operators on the production lines.

Goal

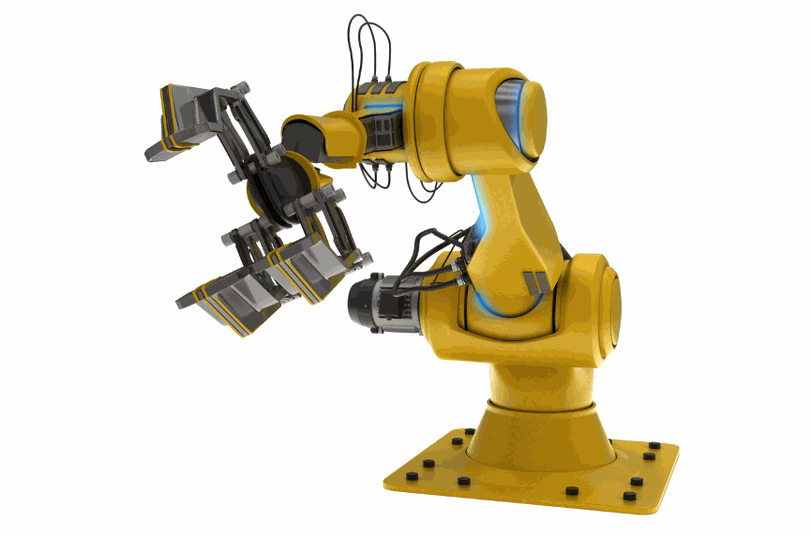

The chosen cobot is a robotic arm with a payload capacity of 10 kg, a reach of 800 mm and three types of grippers to adapt to the required product.

It is designed to work safely alongside operators as it has sensors that can detect when an operator is nearby, and software to slow down or stop its movements to adapt to the environment.

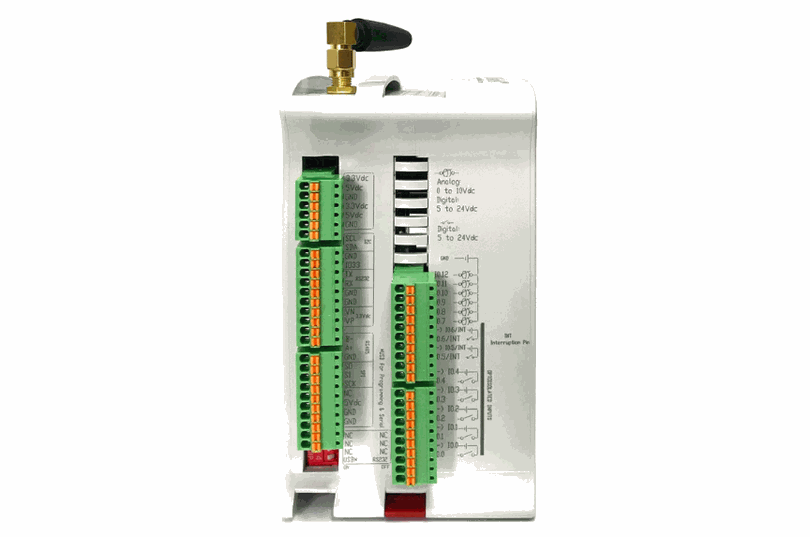

To control and monitor the cobot, the company uses an ESP32 PLC 38R industrial controller from Industrial Shields®.

This industrial PLC is responsible for controlling the cobot's movements, receiving inputs from sensors and cameras, and communicating with the line's production control system.

It runs several customised programs developed by the company's automation engineers in conjunction with our customer, an engineering company. They have adapted the different configurations to match each of the references being manufactured.

Implementation

To monitor the cobot's movements and status information, the company connects an external touch screen to the ESP32 PLC.

The screen displays real-time data on the cobot's status and the production it is performing associated with each of the products: units per minute, time to run the sequence, total parts, pending parts.

Although the cobot model has a relatively low energy consumption, and is an industrial solution designed for intensive use, energy consumption is monitored, and the movements of both the cobot and the critical elements or those most likely to wear out are saved. This information will facilitate preventive maintenance of the cobot.

Advantages and benefits of implementing an ESP32 PLC for robot monitoring

Accurate tracking

It integrates with cloud services, enabling real-time data analysis, remote management and continuous improvement of production processes.

Connectivity

The ESP32 PLC can be easily integrated with other control and monitoring systems, allowing for a higher degree of automation and improved process efficiency.

Flexibility

Thanks to open source platform programming, it is possible to easily customise the code for optimal production monitoring and control.

Enhaced safety

Additional safety measures such as proximity sensors or speed limits can be incorporated to prevent collisions and protect workers.

Dual core, dual power

Thanks to the dual core, processes and communications are managed separately. This ensures optimal execution of each task.

Remote management

Thanks to the installation of PLCs, it is possible to remotely manage the installation and its status.

Quality

Industrial Shields offers quality technology, guaranteed by verification systems and internal audits.

Easy programming

Industrial Shields PLCs can be programmed with the system that best suits the customer's needs.

Why Industrial Shields?

Industrial Shields stands out from its main competitors thanks to the following points:

- Open solution. No licence fees.

- Modular solution: Product specifications can be extended in the future.

- Technical support: Our team is available to help you from the first contact, during the installation phase and up to after-sales.

- Equipment designed and manufactured for industrial use at a competitive price.