Ensuring wine quality with SI-WINE by Sira

Monitoring and Control of the wine fermentation process

Read the Success Story 👇

Situation

Fermentation is a fundamental part of the wine production process, as it determines the quality and taste of the final product.

To ensure proper fermentation and avoid potential problems in the process, it is essential to implement an accurate and reliable control system.

One of the difficulties of this process is the need to continuously monitor key indicators to avoid unexpected or undesired results.

SIRA is an Andorran technology company.

A guaranteed technological partner in the field of robotics, robots and artificial intelligence.

SI-WINE takes care of keeping the temperature within the right limits for the fermentation process to run smoothly, and does so without human intervention.

Project

The system captures temperatures from sensors, which are inserted inside the tanks.

The sensor devices are wireless and can work with WiFi or LoRA technology.

Each unit can control up to 32 devices. And multiple units can be connected without conflict.

The control units are MODBUS compatible and can be integrated with other SCADA systems, to control the energy efficiency of the installation, presence control systems or lighting management.

The temperature sensors are powered by rechargeable batteries, which last for 2 weeks; they give the temperature every 2 minutes, 24 hours a day. The system warns when the batteries need to be changed or recharged.

The probes are food-grade (stainless steel probes + silicone-protected cable) so that they can be in contact with the wine.

The control unit has the connections for the solenoid valves of the cooling jackets of the tanks and the cooling machine.

The connection process always takes into account the open valves, to switch the refrigeration machine on and off, so that there is always a working circuit and to prevent idle operation.

It also has an energy consumption control system during the fermentation process, which allows the energy cost of the fermentation process to be known.

The solution has a system of alerts by email, Telegram or Whatsapp in the event of any contingency that may cause a faulty temperature control, such as an error in a solenoid valve, a fault in the cooling machine or a malfunction of the probe.

In addition, all the traceability of the tank temperatures is recorded in a CSV document compatible with excel.

The automaton is designed to make decisions based on temperature and to notify by Whatsapp or email in case of temperature change.

Refrigeration control

The controller validates the temperatures and, if necessary, switches on the refrigeration and the chambers of the individual tanks.

The parameters of the cooling temperatures are individual and parameterizable for each probe; this makes it possible to control different wine variants independently.

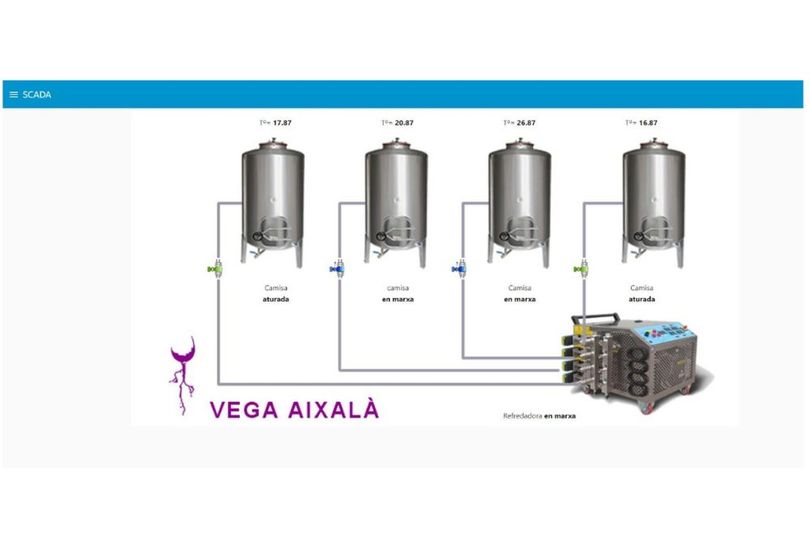

SCADA

The SCADA screen displays:

-

The fermentation process

-

The temperatures in real time

-

The status of the chambers and refrigeration

It also allows you to monitor the maximum and minimum temperatures of the tanks to prevent any rise and/or fall from the optimum limits.

Through SCADA, it is possible to control the sensors for remote and immediate switching on and off.

The system also displays high and low temperature alarms.

Graphs

They show the temperature chain of the different probes.

Export of data (Excel or similar)

The information during the fermentation process is recorded every 5 minutes and the data of all temperatures are saved.

These data are exportable in CSV format. This is an interchangeable format that can be used in Excel or similar applications.

Benefits

Product quality

Thanks to the correct monitoring of the fermentation process, the quality of the wine is assured. A process that could be irreversible in the event of any incident.

Optimization of resources

The versatility of the hardware and software allows a controlled installation with a reduced investment.

Efficient management

The SCADA system allows you to view vital information at all times to ensure the smooth running of the installation.

Why Industrial Shields?

Industrial Shields stands out in this project thanks to the following key points:

Open solution

License free

Modular solution

Scalable project according to needs.

Technical support

Strong customer service ready to help you solve any question regarding the product or solution.

Affordable price

Equipment designed and manufactured for industrial use at a lower price than the competition.