Automated Warehouse with ESP32 Industrial PLC

Discover More >>

Automated Warehouse with ESP32 Industrial PLC

Discover More >>

A company engaged in the online sale of beauty and personal care products needs an automated warehouse system to manage its inventory and improve the efficiency of its operations.

The system must be able to

✅ receive customer orders

✅ pick the products from the warehouse

✅ send them to the packing area.

SUMMARY

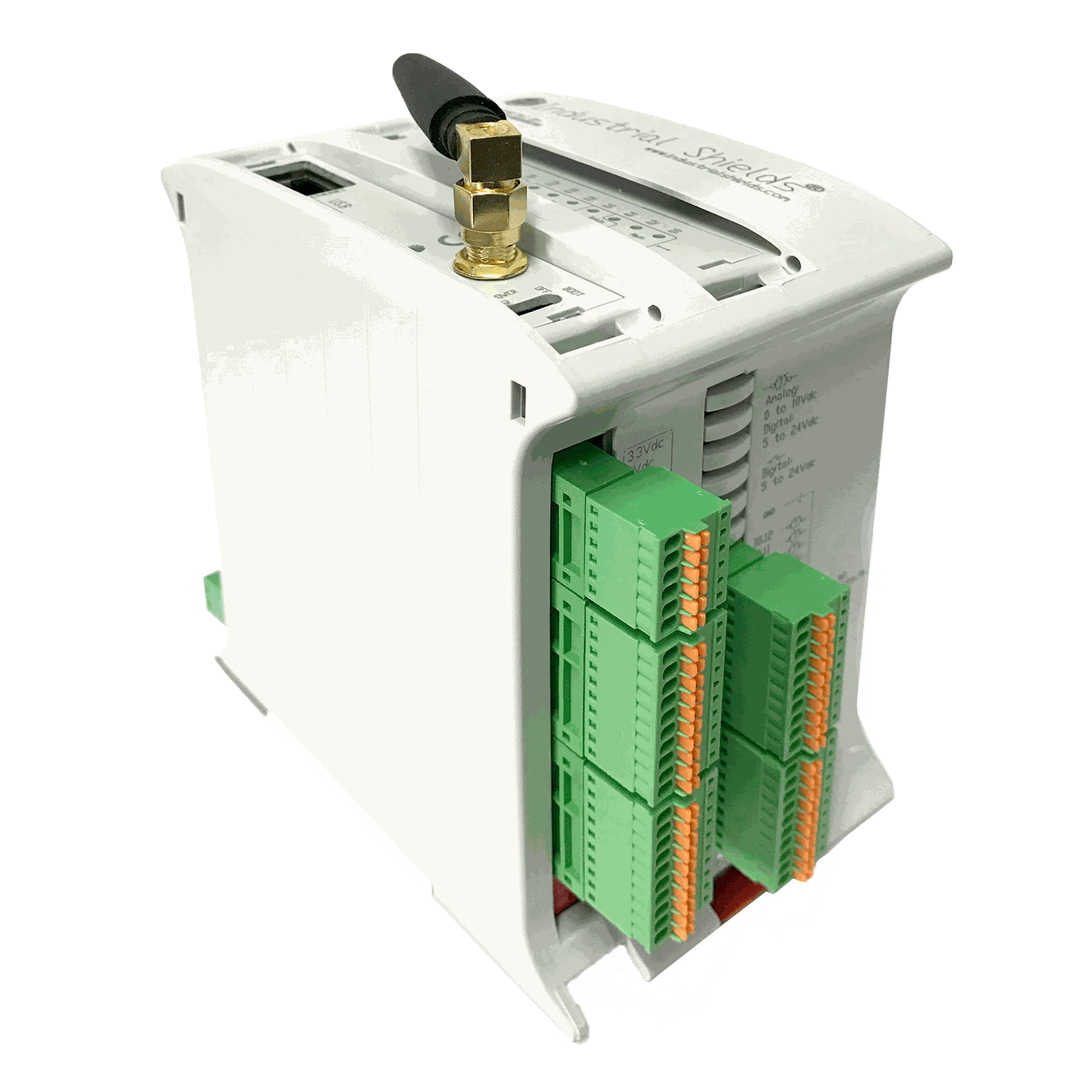

An automated warehouse system using an ESP32 PLC to control product movements is proposed.

The warehouse consists of modular shelves where about a hundred references are managed.

Each rack is equipped with presence sensors that detect the presence of products in the warehouse.

IMPLEMENTATION OF THE WAREHOUSE AUTOMATION

The system consists of three main areas:

Receipt of orders

Warehousing of orders

Packing area

When a customer places an order online, the system records the information and sends it to the storage area.

The ESP32 PLC searches the inventory for the location of the requested products and sends the orders to the robots in charge of picking them up.

Robots are mobile devices equipped with sensors and motors that move along the shelves to pick products.

Once the products have been picked, the robots transport them to the packaging area.

The system uses a network of sensors and cameras to ensure that products are delivered to the correct location.

The packing area is equipped with a workstation that receives the products and prepares them for shipment.

When an order has a grouping of products, operator intervention is usually required in semi-automated processes.

Several barcode scanners register the products and send the information to the shipment tracking system.

When products are grouped together, they are scanned twice, first for the individual products and then for the grouping.

Once the products have been correctly packaged, the system leaves them in the shipping area.

The project also includes the labeling of the packaging that the customer will receive, regardless of whether they are individual products or groups of products, since this information has already been saved during the process for later management.

Everything is synchronized with the ERP:

- to print the label

- request for collection from the parcel company

- sending the tracking of your parcel to the customer.

BENEFITS OF THIS AUTOMATION WITH ESP32 PLC

Improves inventory efficiency and accuracy.

Reduces the time required to prepare orders and ship them to customers.

Allows for greater flexibility in inventory management.

Allows for greater flexibility in inventory management.

Reduces human errors in inventory management

and order processing.

Reduces human errors in inventory management

and order processing.

Enables greater order processing capacity

and system scalability.

¿WHY INDUSTRIAL SHIELDS?

Industrial Shields won the project and beat its main competitors on the following points:

OPEN SOLUTION

No licence fees.

MODULAR SOLUTION

Product specifications can be expanded in the future.

TECHNICAL SUPORT

Our support team is dedicated before, during and after the sales and installation process.

EQUIPMENT FOR INDUSTRIAL USE

Equipment designed and manufactured for industrial use and at a very competitive price.