Automation System for Animal Feeding

Automatic feeding and accurate rations allow an efficient use, which results in healthy growth and production improving.

PLC Arduino for Farming Automation

This project is designed to make an animal feeding system for all kinds of use; cattle raising, farms, horse stables and many more. The feeding process will be automatized using an industrial controller which controls the feeders and will have a track of the food to settle up periods, quantities, and food kinds.

This industrial automation application could be applied remotely using an Ethernet industrial PLC based on Arduino if necessary and the information can be accessed wherever you want, through a VPN connected to our MQTT server.

This database data will be shown on a Panel PC based on Raspberry Pi 4 that will monitor all the information. The analysis of the information should help in a continuous improvement cycle.

Summary

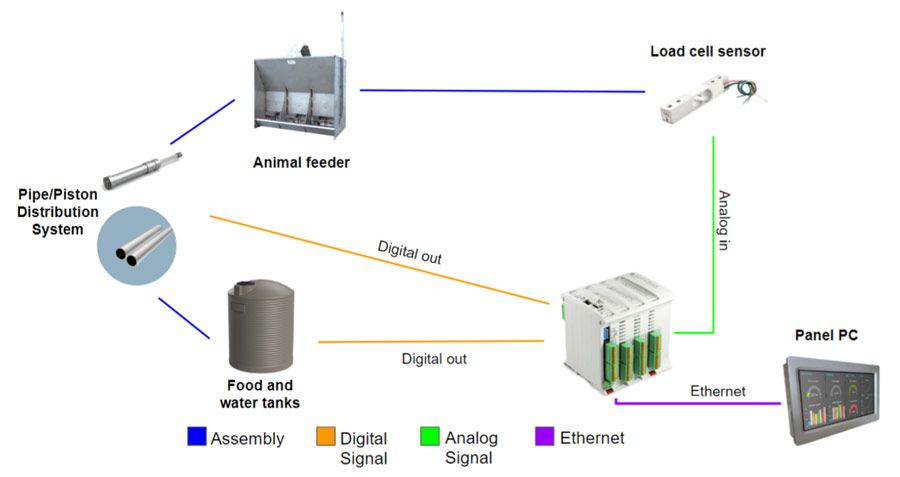

There will be some load cells sensors in the feeders. They might send the food weight data to the controller Arduino, where the data acquisition will be processed. Considering this and the specific orders established by the animal carers (kind of food, temperature, etc.), the open source based PLC may send the order to the feeding system which will dispense the correct amount of food.

All this information can be motorized through the panel PC, where you can control and configure all the system parameters.

In the Panel PC, there will also be a broker server (MQTT) that is responsible for receiving and sending data between the industrial Arduino and the Panel PC.

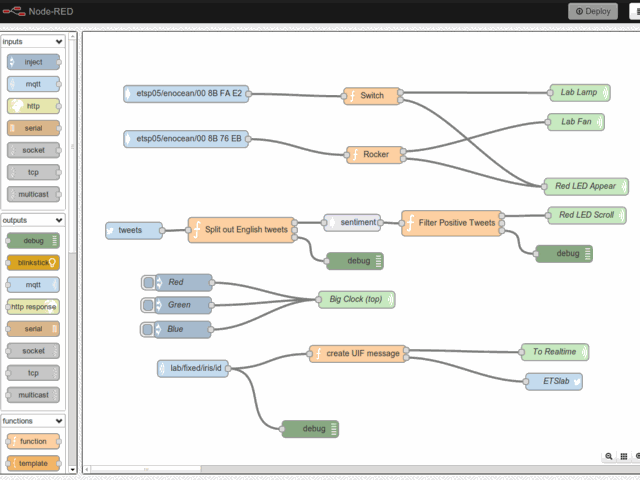

To monitor the data, Node-Red will be used.

Goals

The main points to achieve are as follows:

-

Animal feeding.

-

Food amounts motorized 24/7.

-

Measurement and control of food parameters easily managed through the panel.

-

The distribution system will provide the right amount of food, even medicine if they are necessary.

-

There will be an evacuation system to throw off the remaining food and a cleaning one to take care of the system.

-

All the food, medicines and cleaning liquids may be stored in tanks and distributed through a gravity pipe system or a piston one.

-

Check the M-DUINO PLC ARDUINO ETHERNET & WiFi & BLUETOOTH LE 19R I/Os RELAY/ANALOG/DIGITAL PLUS

Conclusion (Hardware)

Each feeder will have a load cell sensor which collects data and might send it to the programmable logic controllers to control the food and state levels. Programming the PLC or directly managing it through the panel, you can establish all the food parameters, as well as the water, medicines, cleaning liquids or whatever you want to distribute through the system.

When the parameters are set, the distribution system will start; the tanks will provide the exact food amount through an automatized gate, and it will be given to the animals through a pipe or piston system, depending on which will be the best option for the kind of food choosen (feed is easier to be moved with the pipe gravity system and straw with the piston one).

The mechanism could be easily cleaned because it will include an evacuation section to throw off all the remaining food (using pipes or pistons too) and you can select the right cleaning products to be distributed for all over the place and evacuated through a drain.

All the options said in this post and many as you can think will be controlled and monitoritzed through the panel that could be fixed or remotely controlled using the Ethernet adaptation previously detailed (using a M-Duino and a proper server).

Do you want to receive more information about Automation Solutions?

Open Source technology allows you to develop your Monitor applications.

Just fill the form and we will send you several examples about how to use Open Source based devices on your projects.