Introduction

RS-485, also known as EIA-485, is defined as a differential multipoint bus system; it is perfect to transmit data with high speed to ranges up to 12m. One of its most important characteristics is that its twisted pair of cables reduce the noise-induced in the transmission line. Multiple receivers may be connected to such a network in a linear, multi-drop bus. These characteristics make RS-485 useful in industrial control systems and similar applications.

Previous reading

We recommend you read the following posts in order to understand the program of this post. We used the following blog posts to do this example:

How to program our industrial PLC with Arduino IDE How to install Industrial Shields boards in the Arduino IDE.

Requirements

In order to work with serial TTL communication, you will need any of our industrial programmable logic controllers for industrial automation:

Industrial Shields controllers: Wifi & Bluetooth Controller Family, Ethernet Controller Family, GPRS / GSM Controller Family.

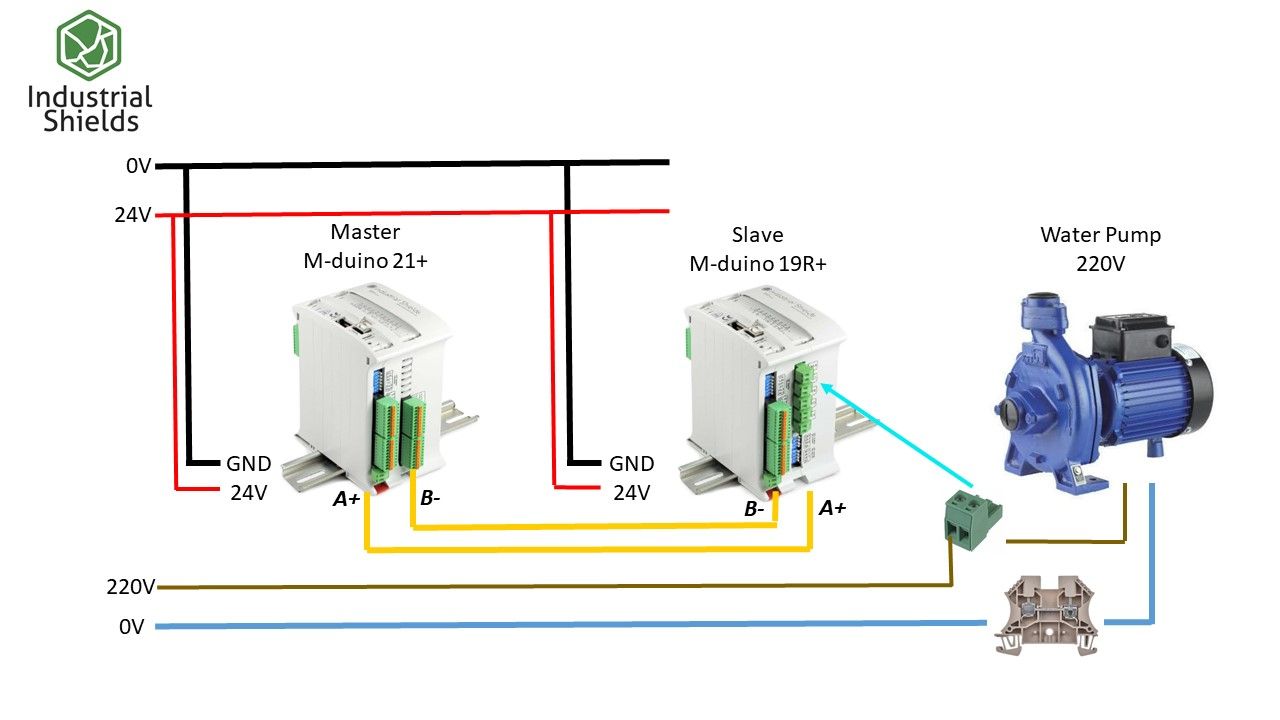

Hardware

To make the connection between the devices, we follow the schematic below.

Software

The following code has the function of communicating the Master and the Slave sending the instruction to activate the relay to turn on the water pump.

An example of Simplecomm Master communication:

#include <RS485.h>

#include <SimpleComm.h>

// Create SimplePacket for sending and receiving data

SimplePacket packet;

// Define master address

uint8_t masterAddress = 0;

// Define slave address to communicate with

uint8_t slaveAddress = 1;

// Value to send as packet data

int value = 5;

////////////////////////////////////////////////////////////////////////////////////////////////////

void setup() {

Serial.begin(9600L);

// Start RS485

RS485.begin(19200L);

RS485.setTimeout(20);

// Start SimpleComm

SimpleComm.begin(masterAddress);

}

////////////////////////////////////////////////////////////////////////////////////////////////////

void loop() {

static unsigned long lastSent = millis();

// Send packet periodically: once per second

if (millis() - lastSent >= 10000) {

// Set request packet data

packet.setData(value);

// Send request to slave

if (SimpleComm.send(RS485, packet, slaveAddress)) {

lastSent = millis();

Serial.print("Sent value: ");

Serial.println(value);

}

}

// Get responses

if (SimpleComm.receive(RS485, packet)) {

// Update value from the response

value = packet.getInt();

Serial.print("Received value: ");

Serial.println(value);

}

}

An example of Simplecomm Slave communication:

#include <SimpleComm.h>

// Create SimplePacket for sending and receiving data

SimplePacket request;

SimplePacket response;

// Define slave address to communicate with

uint8_t slaveAddress = 1;

////////////////////////////////////////////////////////////////////////////////////////////////////

void setup() {

Serial.begin(9600L);

// Start RS485

RS485.begin(19200L);

RS485.setTimeout(20);

// Start SimpleComm

SimpleComm.begin(slaveAddress);

}

////////////////////////////////////////////////////////////////////////////////////////////////////

void loop() {

// Get requests

if (SimpleComm.receive(RS485, request)) {

int value = request.getInt();

Serial.print("Received value: ");

Serial.println(value);

if ( value==5){

digitalWrite(R0_8,HIGH);

delay(5000);

digitalWrite(R0_8,LOW);

}

// Process value

//value++;

// Send response to the request packet source

response.setData(value);

if (SimpleComm.send(RS485, response, request.getSource())) {

Serial.print("Sent value: ");

Serial.println(value);

}

}

}

#include <SimpleComm.h>// Create SimplePacket for sending and receiving data

SimplePacket packet;

// Define master address

uint8_t masterAddress = 0;

// Define slave address to communicate with

uint8_t slaveAddress = 1;

// Value to send as packet data

int value = 5;

////////////////////////////////////////////////////////////////////////////////////////////////////

void setup() {

Serial.begin(9600L);

// Start RS485

RS485.begin(19200L);

RS485.setTimeout(20);

// Start SimpleComm

SimpleComm.begin(masterAddress);

}

////////////////////////////////////////////////////////////////////////////////////////////////////

void loop() {

static unsigned long lastSent = millis();

// Send packet periodically: once per second

if (millis() - lastSent >= 10000) {

// Set request packet data

packet.setData(value);

// Send request to slave

if (SimpleComm.send(RS485, packet, slaveAddress)) {

lastSent = millis();

Serial.print("Sent value: ");

Serial.println(value);

}

}

// Get responses

if (SimpleComm.receive(RS485, packet)) {

// Update value from the response

value = packet.getInt();

Serial.print("Received value: ");

Serial.println(value);

}

}

An example of Simplecomm Slave communication:

#include <SimpleComm.h>

// Create SimplePacket for sending and receiving data

SimplePacket request;

SimplePacket response;

// Define slave address to communicate with

uint8_t slaveAddress = 1;

////////////////////////////////////////////////////////////////////////////////////////////////////

void setup() {

Serial.begin(9600L);

// Start RS485

RS485.begin(19200L);

RS485.setTimeout(20);

// Start SimpleComm

SimpleComm.begin(slaveAddress);

}

////////////////////////////////////////////////////////////////////////////////////////////////////

void loop() {

// Get requests

if (SimpleComm.receive(RS485, request)) {

int value = request.getInt();

Serial.print("Received value: ");

Serial.println(value);

if ( value==5){

digitalWrite(R0_8,HIGH);

delay(5000);

digitalWrite(R0_8,LOW);

}

// Process value

//value++;

// Send response to the request packet source

response.setData(value);

if (SimpleComm.send(RS485, response, request.getSource())) {

Serial.print("Sent value: ");

Serial.println(value);

}

}

}

#include <RS485.h>

Subscribe to our YouTube channel if you want to keep up to date with our tutorials.

How to connect two industrial PLCs through RS-485