1. Introduction

2. How do we program your PLCs?How do we program your PLCs?

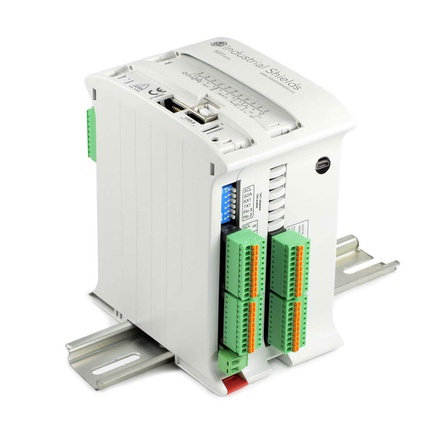

3. How do IS boards work? How can I install it?

4. Is there any PLC with Wifi communication?

5. How can we use the TPC/IP protocol with your products?

6. Where can I find help to start programming I/OS and communication protocols?

7. Which is the electrical consumption of our PLCs?

8. What does it mean that the PLCs work at 12-24V?

9. Where can I find examples to program my PLC?

10. What are the benefits of industrial automation?

11. Can I use an Arduino board for Industrial purposes? Can Arduino be used as a PLC?

12. Is Arduino/Raspberry better than PLCs?

13. Is PLC programming easy?

Introduction

Is there any PLC with Wifi communication?

How can we use the TCP/IP protocol with your products?

Where can I find help to start programming I/Os and communication protocols?

What does it mean the M-Duino/Ardbox works at 12-24V?

Which is the electric consumption of your PLCs?

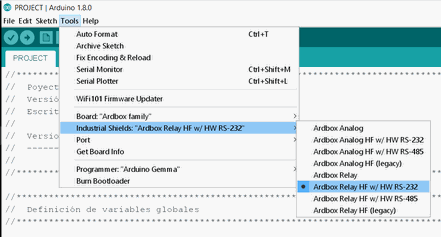

How do we program your PLCs?

Our pieces of equipment can work with different Open Source Software for different purposes, check out the software section of our website:

Software possibilities

We also have created some libraries to interact more easily with our PLCs. Get all the information in the following post:

How do IS boards work? How can I install it?

Is there any PLC with Wifi communication?

Yes. Enter the following link to discover the family of PLCs with built-in WiFi & Bluetooth Low Energy modules!

WiFi & BLE family PLCs

How can we use the TPC/IP protocol with your products?

We actually have a post that explains how to create a TCP client on Arduino Based PLC.

TCP Client on Arduino based PLC

Where can I find help to start programming I/OS and communication protocols?

That's what our help pages are for, where you'll find how to configure and program each family of PLCs.

Which is the electrical consumption of our PLCs?

All the maximum consumptions of our PLCs are shown in all the user guides of each product. However, the standard consumption of our products is about 30VAC.

What does it mean that the PLCs work at 12-24V?

That our PLCs work between 12 and 24V means that in order to turn them on, they must be connected to a power supply that works between this range, so any value that works within this range is valid to power our PLC and Panel HMI units. If supplied with less than 12V, the board may become unstable. If you use more than 24V, the voltage regulator may overheat and damage the board.

Where can I find examples to program my PLC?

Each PLC User Manual contains all the information regarding general information, configuration parameters and how to download the Industrial Shields boards and programming instructions among other interesting information.

On the Industrial Shields website, there is a blog section where you can find some practical examples to program all of our products.

Finally, you can also check the Industrial Shields GitHub pages with different libraries and examples for each one:

What are the benefits of industrial automation?

- Reduces Costs. The automated data analysis reduces the risk of machine failures and service interruptions.

- Increases Productivity. As the production can work 24 hours a day, seven days a week.

- Enhances Quality. It deletes human error and improves the quality and homogeneity of the products offered. Therefore, automated production processes have a longer duration, stability and solidity when managed with an automation system.

- Industrial Safety. It is always safer to use industrial automation in specific working conditions, where the damage caused to people can be much more serious.

- Accurate Results. The accuracy improves when the automation of data collection takes place.

- Better Working Conditions and Value-Addition. The conditions for employees working where an industrial automation system has been implemented, spend their time on high value-added tasks.

- Industrial Communication. Industrial automation allows the company to collect, at all times, all the information provided by the machines or devices from the place where they are located. Therefore, the equipment monitoring and production traceability are much more controlled.

Can I use an Arduino board for Industrial purposes? Can Arduino be used as a PLC?

Arduino is a microcontroller board that, although it turns out to be very useful for testing in small/medium projects, it has some limitations in terms of an industrial environment:

- It has limited I/O.

- Its inputs and outputs are not protected, so they are not protected from noise, surges, or short circuits. The I/O from our PLCs are isolated to avoid this.

- The recommended range of voltage in the Arduino board is between 7 and 12 volts. Instead, the PLC input voltage is between 12 and 24V, which allows better management of industrial resources.

- The Arduino boards usually need external hardware to be able to have LoRa, DALI, GPRS, ModbusRTU or WiFi communication, among others. Our PLCs already incorporate it.

- The Arduino board does not have a DIN rail to facilitate fitting into an electrical panel.

Using Industrial Shields Arduino, ESP32 and Raspberry Pi-based PLCs, these problems are solved due to the hardware that involves the internal boards preparing them for hazardous environments that are found in industries and automation.

Is Arduino/Raspberry better than PLCs?

It always depends on the purpose. As the PLCs are prepared for industrial environments because of their safety and quality, among others, the PLCs are always recommended for industrial applications, since the intention is to guarantee data integrity and greater reliability. Whilst Arduino and Raspberry Pi boards can be very useful for small/medium projects like testing industrial applications, which will later be implemented with PLCs.

Is PLC programming easy?

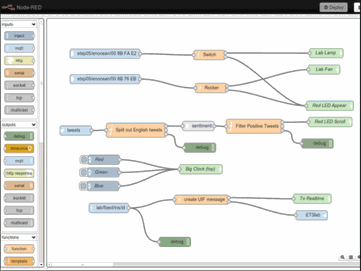

Our Open Source hardware allows us to work with a great variety of programming languages. Thus, for PLCs based on ESP32 or Arduino, we use the Arduino language (C / C ++), and for those based on Raspberry Pi, we use a wide variety of languages since the operating system itself allows it, such as Python, Javascript, Go or Unix Shell, among others.

There are also open-source platforms, such as Node-RED, through which it can be programmed in a very simple way with flow nodes. In this way, the nodes that the user only has to drag and drop contain invisible code behind them, which already carries out the necessary actions so that the programmer does not have to mince code.

On this same platform, there are official nodes for Arduino, Raspberry Pi or Industrial Shields to be able to program the boards in a very simple way and to be able to activate and deactivate all the outputs. Likewise, it is also allowed to get the input values.

In addition, there is a large community behind Arduino, ESP32 or Raspberry Pi, which makes projects and examples in such a way that it is constantly shared. So, even if you don't know how to program, it is very easy to program the PLCs.

FAQ Simple Questions