Monitoring Water Consumption with ESP32 PLC

Saving of water resources through monitoring and analysis 👇

Read More >>

SITUATION

For some years now, the planet has been suffering from a shortage of natural resources. In this context, it is important to know how to optimise and rationalise them as far as possible.

Although the quantity and quality of water in Andorra do not seem to be a cause for concern, FEDA would like to have as much information as possible on the consumption of fresh water.

The leitmotiv of the project is to control the cold water in FEDA's buildings in order to integrate them into the company's energy efficiency plan.

The system will make it possible to know in real time the consumption of cold water, and compare it with the consumption averages to avoid leaks or unnecessary losses of water.

SIRA is an Andorran technology company.

A guaranteed technological partner in the field of robotics, robots and artificial intelligence.

WATER CONSUMPTION PROJECT

In order to monitor water consumption, the appropriate water meters are installed for each building, depending on the pipe cross-section.

Each meter is fitted with a pulse emitter system, parameterised by NFC.

Each pulse corresponds to 1 liter of water, with a duration of 300ms per pulse.

The counters are by Salvador Escoda, and the pulse emitters by Bmeters.

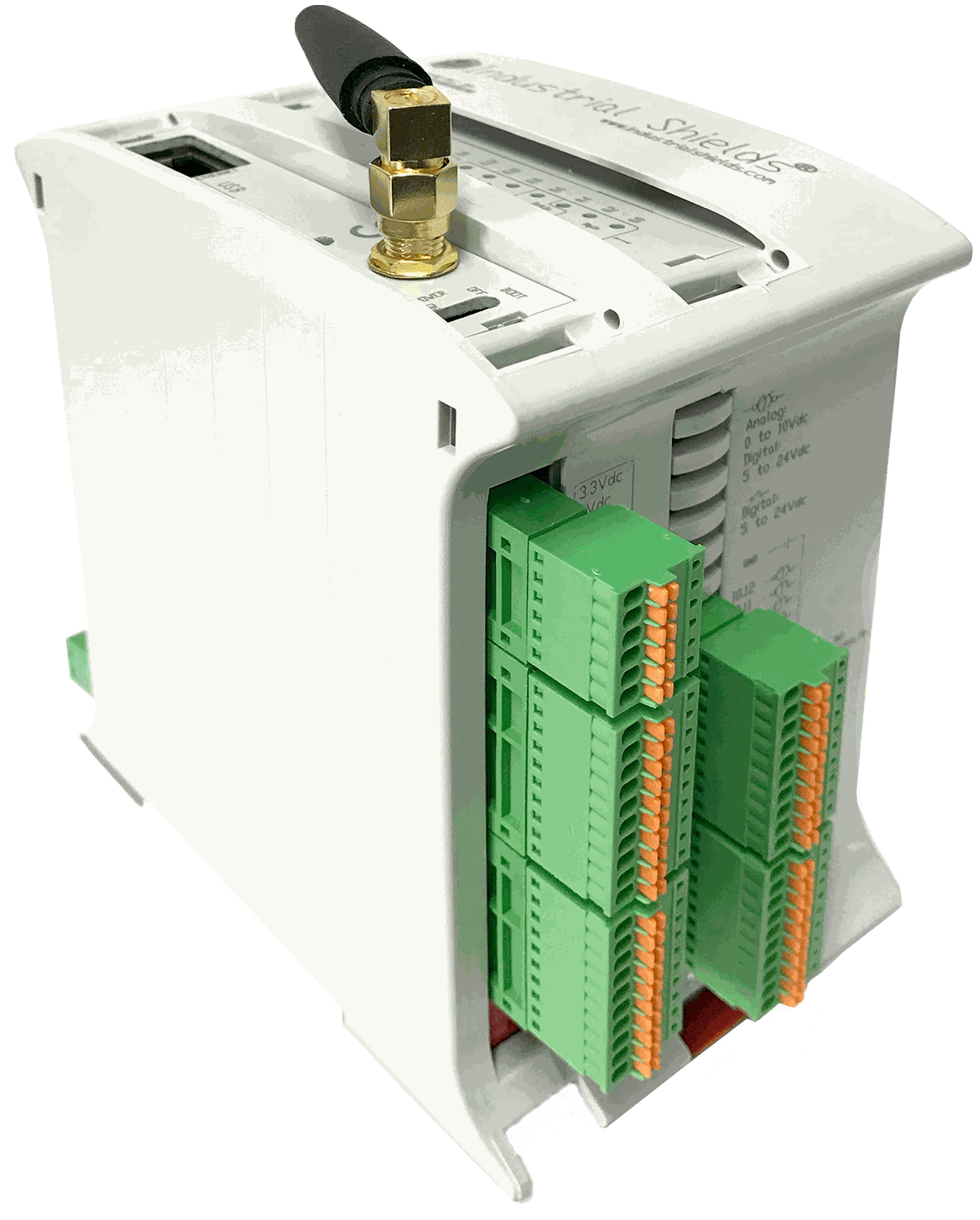

To read the pulses, Industrial Shields PLCs (Programmable Logic Controllers) are installed, which allow up to 12 analogue and digital inputs/outputs, and different communication protocols.

The communication protocol to be used in this case is TCP MODBUS, a standard industrial protocol also used by the Circutor PowerStudio software, which works over Ethernet.

The PLCs are programmed with C++; they pack and send the pulses with a total value of liters for each of the meters, in order to avoid losses due to collisions or lack of communication with the buildings. Thus, even if there is a communication failure, the emitted pulses will never be lost.

In addition, the PLC has a µSD card type memory to store the variables and, even in the event of a power cut, the total number of pulses recorded would not be lost.

Via MODBUS TCP, the PLCs send the frames over Ethernet to be captured by the SCADA (Supervisory Control And Data Acquisition) system.

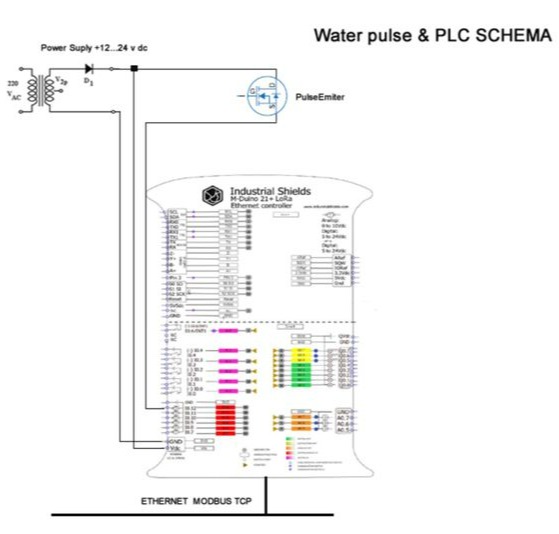

DIAGRAM - CONNECTING THE GENERATOR TO ESP23 PLC

The diagram shows the connection of the pulse generator to the PLC.

Note:

The outputs of the pulse emitter IWM-PL3 are of type N-MOS (NPN), and can supply up to 30V dc and max. 100mA.

SCADA SYSTEM FOR THE SOLUTION

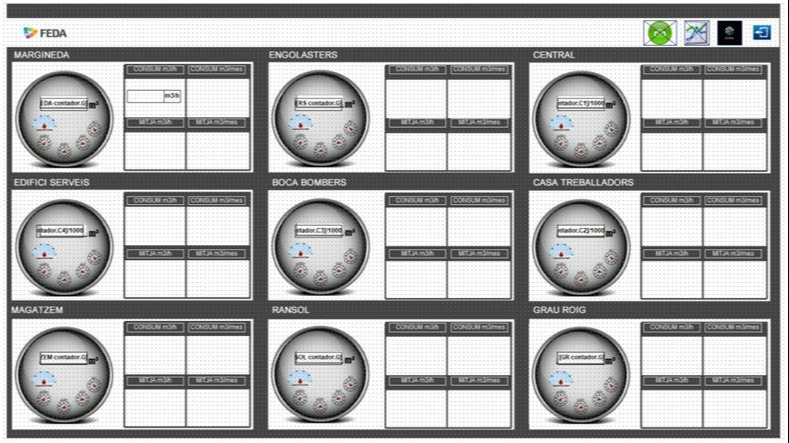

The SCADA screen allows you to display:

- the meter for each of the water inlet pipes.

- the averages in m3/h

- the monthly water consumption

It also shows a table to export to Excel the values per day and time of any meter, and a graph to compare and visualise the consumption of all the parameterised meters over time.

Through the SCADA system, it is possible to set up a system of alarms and warnings to notify when consumption is outside the pre-set parameters. This allows system managers to quickly identify possible faults and take the necessary measures to correct them.

In addition, the information collected by the SCADA system can be used to analyse trends in water consumption and optimise the operation of the system, thereby reducing costs and improving efficiency.

In short, the SCADA graph and the information it displays through the monitoring installation is an invaluable tool for the effective management of water resources and for ensuring optimal and efficient operation.

BENEFITS OF THE CONTROL CONSUMPTION WITH ESP32 PLC

Global control

The installation of PLCs makes it possible to control the entire solution, monitor consumption and save water resources.

Data security

The µSD card type memory of the PLCs helps to maintain the integrity of the data in the event of faults in the electrical supply.

Effective management

The SCADA system allows you to analyse water consumption trends, reduce costs and improve system efficiency.

¿WHY INDUSTRIAL SHIELDS?

Industrial Shields won the project and beat its main competitors thanks to the following points: