IIoT

The Industrial Internet of Things (IIoT)

What is it and how will it affect manufacturing?

The Industrial Internet of Things (IIoT)

IIoT is part of a broader concept known as the Internet of Things (IoT), which is revolutionising the way we interact with the digital and physical world. At its core, IoT is about connecting a variety of smart devices and objects through a network, allowing them to efficiently collect and share data.

However, when talking about IIoT, the focus is specifically on industrial and commercial applications of this technology, leading to a diverse set of possibilities and challenges.

The IIoT drives digital transformation in industrial sectors, including manufacturing, energy, logistics, agriculture and healthcare, among others. Here, the goal is to harness the connectivity and intelligence of devices to increase efficiency, reduce costs and improve decision-making.

Some of the most prominent applications of the IIoT could be:

Smart Manufacturing

IIoT enables smart factories with connected machines, sensors and systems. It optimises processes, monitors machine health in real time and ensures continuous high quality production.

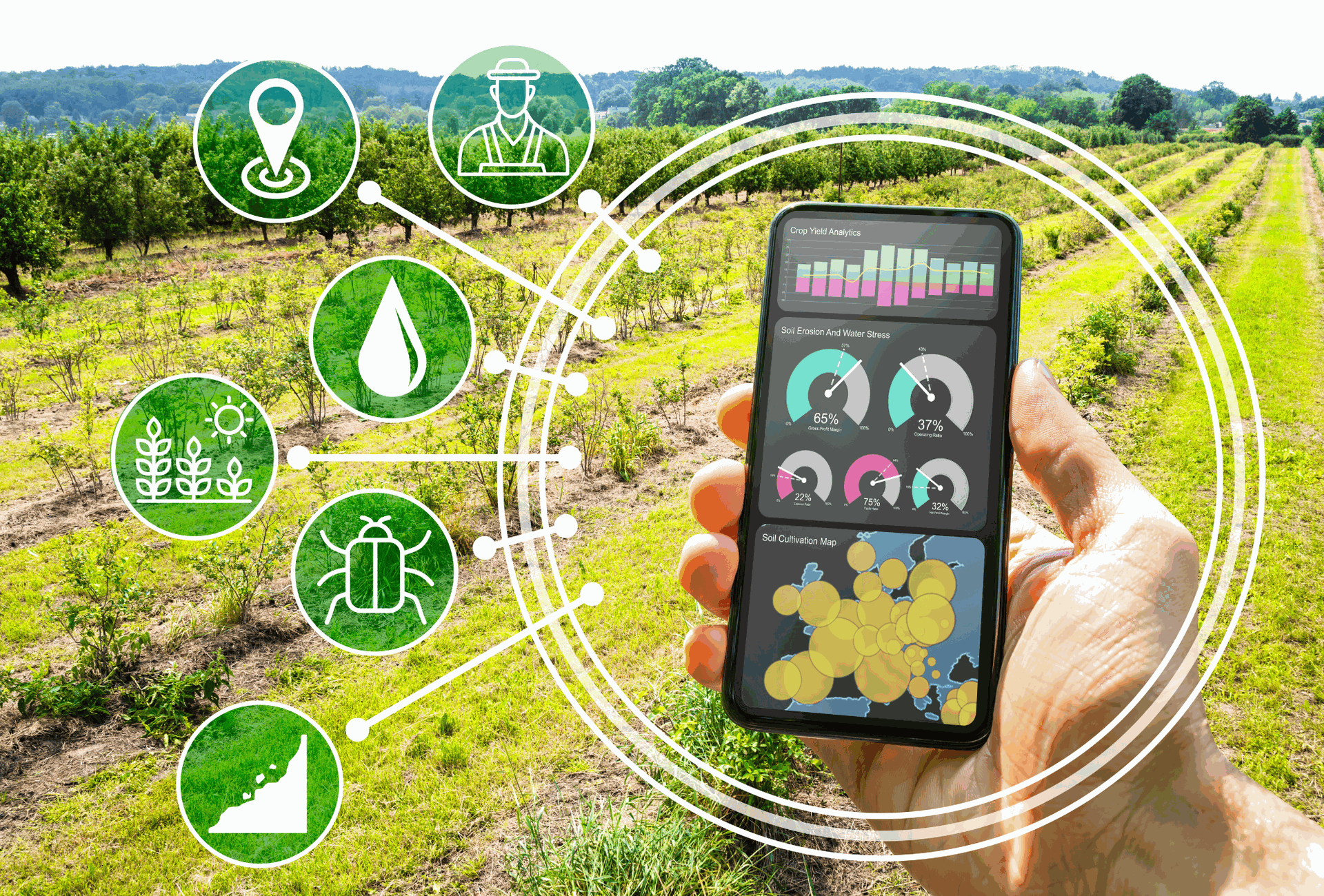

Precision Agriculture

Farmers use IIoT to monitor soil conditions, weather and crop health through sensors. This data-driven approach optimises irrigation, pesticide use and yields, increasing productivity and reducing costs.

Safety and Predictive Maintenance

IIoT enables advanced safety and predictive maintenance systems. Sensors and cameras detect anomalies and risks in industrial environments, providing real-time alerts to prevent accidents and ensure continuous operations.

Logistics Optimisation

The IIoT enables real-time tracking of vehicles, containers and goods in transport and logistics. This leads to more efficient route planning, reduced fuel costs and on-time deliveries.

Smart Cities

IIoT can improve urban infrastructure by monitoring and controlling various urban systems, such as traffic lights, waste management and energy consumption, to improve efficiency and overall quality of life.

What are the benefits of IIoT?

The application of the IoT to the productive industry is called IIoT (or Industrial Internet or Industry 4.0). The IIoT will revolutionize manufacturing by enabling the acquisition and access to much larger amounts of data, at much higher speeds and much more efficiently than before. Through the PLCs and the Panel PC's of Industrial Shields, IIoT solutions can be implemented connecting devices in productive companies, autonomous installations, etc.

The IIoT can greatly improve connectivity, efficiency, scalability, time savings and cost savings for industrial organizations. Companies are already benefiting from the IIoT through cost savings by applying it to predictive maintenance, improved security and other operational efficiencies. IIoT smart device networks allow companies to identify data silos and connect their resources, data and processes from production plants to decision-making centers. Managers can use IIoT data to get a complete and accurate view of how their company is working, which will help them make better decisions.

Some of the most important benefits are:

Advanced Connectivity

The IIoT enhances the connection of PLCs with other devices, enabling real-time data collection and exchange to monitor industrial processes.

Remote Monitoring

PLCs connected to the IIoT enable remote monitoring and control of industrial processes, facilitating troubleshooting, preventive maintenance and real-time, data-driven decision making.

Process Optimisation

The IIoT collects sensor and PLC data to analyse and optimise industrial processes, improving productivity and reducing costs.

Energy Management

In industrial automation, PLCs linked to the IIoT monitor energy consumption in real time for more efficient management and identification of areas for improvement.