PLC Modbus Communication Protocols also Fight the COVID-19

Industrial Arduino Automation for the COVID-19

The use of today's technology is a very effective and fast way to make information flow everywhere in a short time.

The Modbus communication protocol by Modicon is a worldwide-extended protocol that was born in 1979. The two most common types of it are Modbus RTU and Modbus TCP/IP.

Summary

In a world where most things are monitored by technology, you cannot be left behind.

Coronavirus has been living with us for the last six months and still has time left, so every little step to overcome it counts. This is where Modbus communication protocols take over control and helps us humans to make data travel around the world.

There are two main Modbus protocols and both play an important role in the ¡data transferring work, furthermore, they work together. These communication protocols are included in our Arduino automation based industrial controllers and they work with Ethernet, a connection that our industrial PLC automation devices also have.

The benefits of using these two Modbus protocols are:

-

Open source code and no license fee required.

-

Widely supported by HMIs and/or SCADA software.

-

Easy to use.

-

Various industrial automation equipment can be easily integrated.

-

Low development cost.

-

Widely known in the industry.

Goals

The objective of the system we designed is to be able to have a very extended registry of the body temperature, at world-wide level if it is possible, so that the statistical control and the end of the Coronavirus can be nearer. To achieve this, we are going to use the Industrial Shields equipment.

Conclusion (hardware)

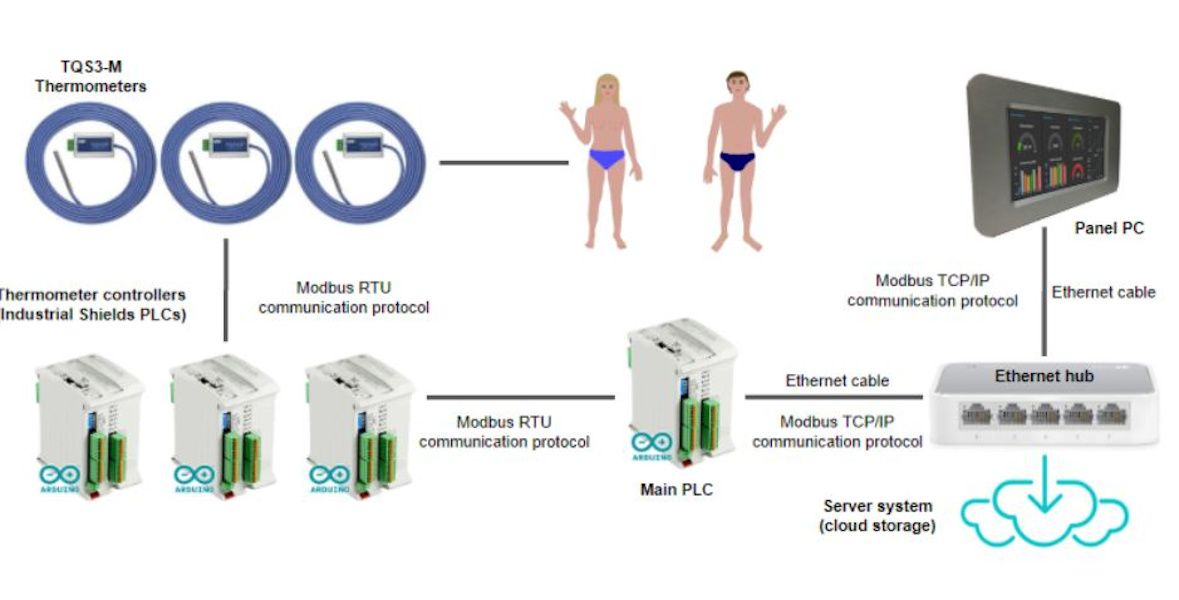

The TQS3-M thermometer will be the first thing used, by measuring the temperature to the users. The thermometer will send the users' temperature data to the Industrial Shields PLC Arduino via Modbus RTU, which is a binary communication protocol with a continuous flow. After this, the controllers will use the same communication protocol to forward the data to the main PLC controller Arduino.

A new communication protocol will be used from the main Arduino PLC. This will be Modbus TCP/IP, which reaches the devices through the Ethernet network. The operation of this protocol is very similar to the RTU one, but it uses the TCP (Transmission Control Protocol) and the IP (Internet Protocol).

The main Industrial Shields controller will send the data to an Ethernet hub that will be connected to a Server system and a Panel PC, also from Industrial Shields.

On the one hand, the Server system will work as a cloud storage and will be ready to store all the users' temperature data.

On the other hand, the Panel PC will be a visible interface for the instructions that the main PLC (master) monitors and/or the data that it receives from the other Programmable Logic Controllers (slaves).

If you are thinking of automating your company, contact us. We will help to find the best open source based solution to monitor and control your facilities.

Ask for more information

Fill in the form below if you need more information

Do you want to receive more information about Industrial Automation?

Open Source technology allows you to develop your Monitor applications.

Just fill the form and we will send you several examples about how to use Open Source based devices on your projects.