Industrial Automation with Arduino, Raspberry Pi and ESP32

If you have arrived here, it is possible that you are considering implementing an automation, monitoring or control solution, but you do not know where to start. Maybe you are looking for alternatives to improve your current solution, or it is for another reason. Anyway… do you want to know how you can increase productivity in your company and reduce costs? You've come to the right place.

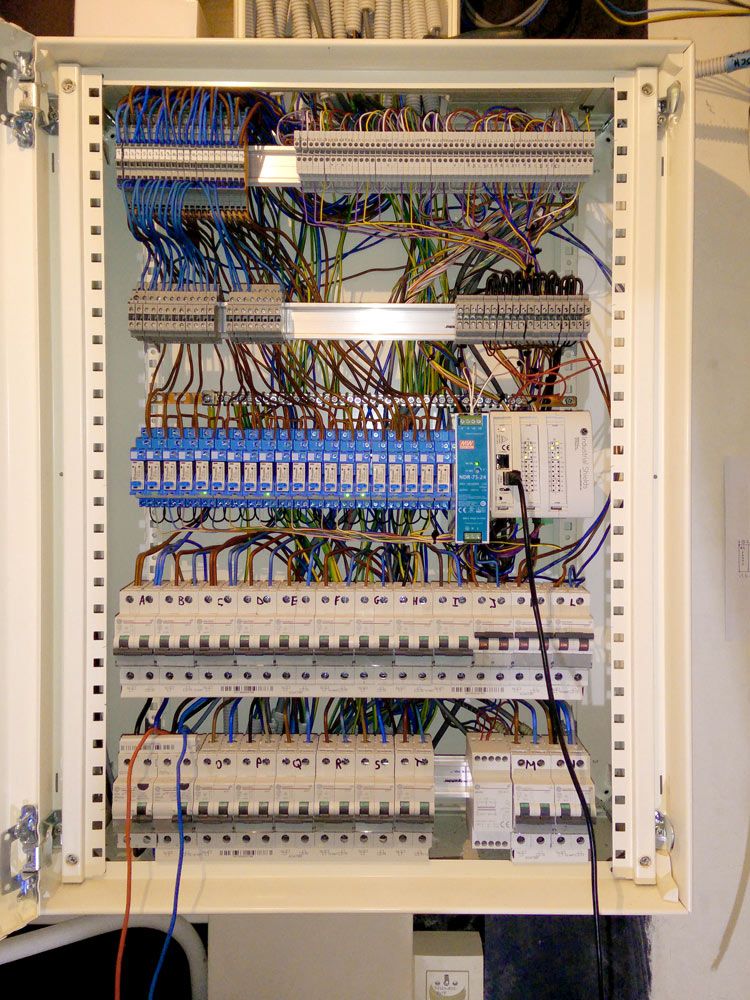

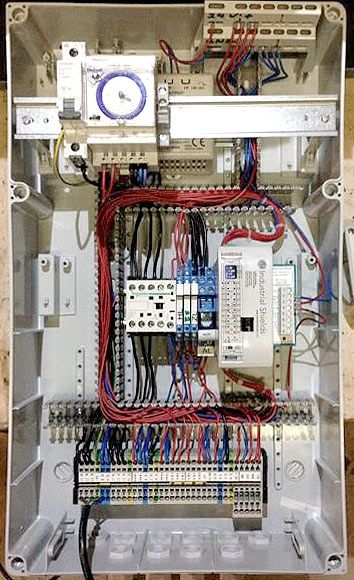

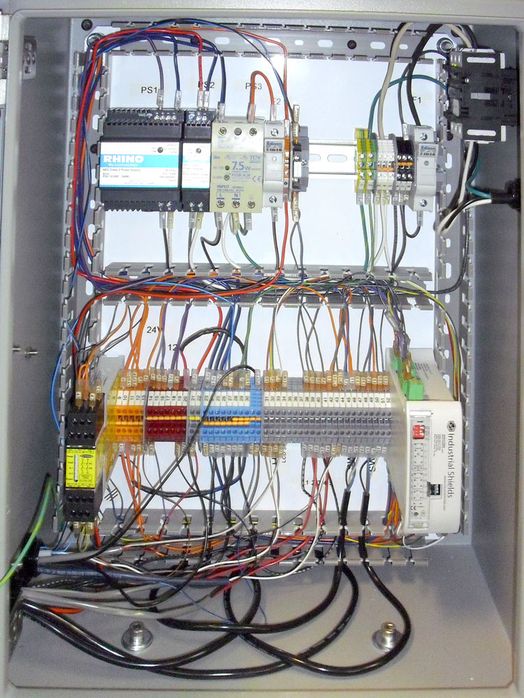

The objective of this project was to implement an industrial automation solution, mainly to increase productivity and be more efficient with the other resources that our client had.

As you must know, industrial automation, monitoring and control improves productivity by the standardization of processes, resulting in:

- Cost reduction. In fact, it is estimated that organizations can reduce their costs by 25 percent to 50 percent.

- Improved quality with lower risk.

Thanks to industrial automation and monitoring, our client transformed testing and quality control because the increased capacity industrial automation provides allowed them to move from spot checks to 100 percent quality control, which reduces the error rate to nearly zero. When machines take on formerly manual tasks, the risks of human error also decrease.

Industrial automation and monitoring have uncountable benefits for you and also, can help you with some of the issues that you or your company are currently facing:

- It boosts production rates.

- Productivity increases.McKinsey Institute estimates that automating different processes can increase the growth of productivity by up to 1,4 percent.

- The use of material becomes more efficient.

- It enhances the product quality and improves industrial security.

- Furthermore, in tasks where the margin of error can be as high as 10% when performed by a human, a process automation platform can decrease it to as low as 0.00001 percent.

- Collect data easily.

What is Open Source Hardware?

Open-source hardware consists of physical artifacts of technology designed and offered by the open design movement.

The term typically refers to tangible machines and other physical systems which are designed and released to the public in such a way that anyone can study, modify, distribute, build, and sell the design or hardware based on that design.

Organizations expect all software source code to be open to maximize interoperability, it's natural for them to think the same of hardware.

Why do I need Open Source Hardware?

Open Source Hardware has much in common with Open Source Software in that it has many of the same benefits. Open Source Hardware is released under the same copyleft licenses that are used for Open Source Software. Users may combine the two hardware and software more easily with open source.

Firstly, Open Source Hardware ready to use on industrial environments lets you automate installations. The Arduino, Raspberry Pi or ESP32 controllers use Open Source Software, which means that your costs on program, monitoring and data platforms is low in comparison with using other “private” platforms.

Everyone can benefit with this type of hardware. It is so useful because it allows a single researcher to produce and publish a design that all other researchers can utilize. As a result, there is an instant chance to catch up to best practices, allowing research to go further.

The fusion of modern programming choices with established industrial practicality will undoubtedly benefit end users who choose open source for their automation project. Users can combine many methods to acquire exactly what they require.

Open source is also a good fit for a number of semi-industrial applications, such as environmental monitoring, home automation, and agricultural projects.

There are a lot of Open Source Platforms available for automating, monitoring and controlling for industrial applications using controllers or different devices ready to use according to your technical needs. All of them offer you enough flexibility

, safety and robustness

to automate installations, your production plan or all kinds of projects step by step, adapted to your production volume at the moment for an affordable price.

You can see the technical and cost benefits in the following comparison.

Comparison between Raspberry PLC and SIMATIC S7-1500 CPU 1511C-1PN

|

|

Raspberry PLC Configurable

|

SIMATIC S7-1500 CPU 1511C-1PN

|

|

|

|

|

|

Nº of Digital / Analog Inputs

|

Total 37 x 21 x 16 |

Total 25 x 16 + 4x (High Speed Digital Outputs) x 5 |

|

Nº of Digital / Analog Outputs

|

Total 32 x 23 x 9 | Total 18 x 16 x 2 |

|

Nº of Relay Outputs

|

- | - |

|

RS-485 (Y/N) - Quantity

|

x2 |

- |

|

RS-232 (Y/N) - Quantity

|

- | - |

|

Ethernet (Y/N) - Quantity

|

x2 | x2 |

|

WiFi (Y/N)

|

Yes | - |

|

BLE (Y/N)

|

Yes | - |

|

GPRS & GSM (Y/N)

|

Yes | - |

|

Other Communication protocols available I2C, SPI, DALI, LoRA, Serial TTL, ... |

Serial TTL, I2C x1, SPI x1, CAN | USB port: USB - SoMachine - Network |

|

RTC (Real Time Clock)

|

Yes | Yes |

|

Micro SD Slot

|

Yes (intended for the OS image) | Yes |

|

Flash Memory (Arduino/ESP32) RAM (Raspberry)

|

256 KB (8 kB for bootloader) |

256 KB |

|

Clock Speed (Arduino / ESP32) CPU (Raspberry)

|

Broadcom BCM2711, Quad-Core Cortex-A72 64 bits a 1.5GHz | 175 KB for program 1 MB for data |

|

Operative Temperature

|

0ºC to 60 ºC |

-10 to 55°C |

|

Other Features

|

UPS, x2 micro HDMI ports, Auxiliary Port |

High Speed Outputs + 6 High speed counters + PROFINET + Option to add expansion IOs modules |

|

Software License? (Y/N)

|

No | Yes | Simatic Step 7 basic = 183,77€. Full Package: 2.300,00 € |

|

NET Price

|

593,18€ |

1.336,53€ (Price from distributor, not from Siemens®) |

Interested in seeing more comparisons?

See for yourself the benefits of our Open Source Hardware devices.