Controlling HVAC System with Industrial PLC Arduino

Temperature, ventilation and odors control

Arduino Controller for HVAC control

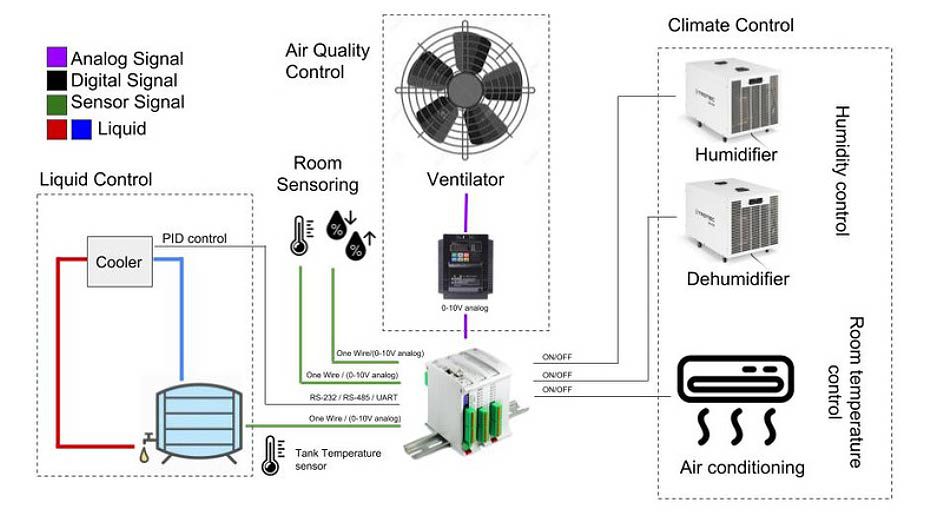

This study case explains the implementation of an HVAC system using controller Arduino equipments for a specific solution in this area.

We refer to an installation of a server immersion cooling system, besides controlling temperature, odors and ventilation of the room where the whole system is installed. All this data acquisition and process control is a crucial part in every industrial installation.

Cooling control

Owing to the plant new requirements, the customer needs a new and powerful refrigerating system to improve the current HVAC installation. It is also important to create an installation model that can be easily replicated, with flexibility to modify the present sequence because it exists the possibility of sharing the oil refrigerator with new server farms, due to the spec of the cooler.

The project is a server farm with an specific refrigerator system based on oil. The particularity of this installation requires a great control and monitoring of several critical parameters. The working temperature of the servers, the humidity, and also the oil odors will serve to maintain the environment clean and also functional.

Goals

The HVAC system has to control a server submerged in a cooling system. The room and the tank has to be inside a certain range of temperature and humidity. There is also a ventilation system which is responsible for reducing oil odors that are in the plant, so the operators can work in it.

Conclusion

The industrial Arduino PLC has to control temperature (room and fluid), humidity and the ventilation of an entire room with two critical elements: temperature and odors, as well.

To control the fluid it is required a PID implementation in the industrial controller with a temperature sensor. The sensor value is compared with a setpoint and the PLC treats the flow to be implemented by the cooler.

The room climate is controlled by a dehumidifier/humidifier and an air conditioning equipment. They are enabled or disabled depending on the values of the temperature and humidity sensors.

The ventilation is treated with a variable frequency drive. The open souce Arduino PLC makes the ventilator rotate faster or slower depending on the odor. The AFD (variable frequency drive) is controlled using an analog signal.

HVAC Scheme