Smart City Compacting Litter Bin with ESP32 Industrial PLC

Reliable and Robust solution with wireless connectivity

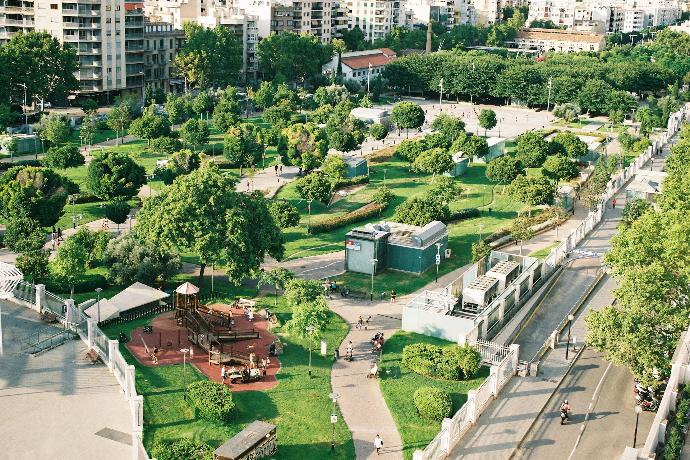

One of the challenges that institutions are working on, especially in cities, is waste management.

On this occasion, our customer proposes a solution that is already spreading in some countries:

a solar compactor litter bin to be installed in the street.

SUMMARY

Our customer needs an element that is going to be in the street, with all that this entails: intensive use, risk of vandalism, etc. Therefore, the litter bin is made entirely of metal for extreme resistance.

It has an internal press and a trolley with wheels to facilitate the emptying process. It also mounts several sensors for automatic pressing processes or for security controls.

It has a sunroof to ensure autonomous operation.

GOALS

The customer's requirements are as follows:

-

Capacity control to carry out automatic compacting.

- Sending notifications in the event of warnings, incidents or alarms.

- Counting the number of compacting operations.

- Weighing of waste.

- Stopping the press with the emptying door open to avoid accidents when handling the trolley.

- Monitoring of battery status and total charge.

- Wireless remote communication.

SOLUTION (HARDWARE)

The system consists of an ESP32 PLC with GPRS and sufficient inputs and outputs to be able to control the entire solution.

It has a press that is triggered as soon as the presence sensor detects that the compaction cycle has to be started.

Different sensors are responsible for synchronising the operation and monitoring whether the control centre needs to be alerted for an operator to empty the bin.

Other sensors also show whether the system is running smoothly.

Another of the control systems installed is the one that allows the use of the waste bin at will if there is no incident that prevents it.

Otherwise, the LED indicates that the bin is not available for use and the waste flap is blocked.

BENEFITS OF THE SYSTEM

Improving sustainability

By compacting waste, the volume of rubbish is reduced, helping to reduce the carbon footprint and reducing the amount of waste sent to landfill.

Saving time and resources

Reduces the number of trips required to remove waste and helps to lower the associated costs for operatives and their means of transport.

More efficient routes

Operators in charge of litter bin emptying and maintenance can better organise their time and be more efficient thanks to the remote information available to them.

Cleaner and more liveable cities

At certain times, some areas of many cities cannot absorb the amount of waste generated. This option substantially minimises this problem.

Scalable system

The system allows Smart City functionalities to be added in the future.

¿WHY INDUSTRIAL SHIELDS?

Industrial Shields won the project and beat its main competitors on the following points:

OPEN SOLUTION

No licence fees.

MODULAR SOLUTION

Product specifications can be expanded in the future.

TECHNICAL SUPORT

Our support team is dedicated before, during and after the sales and installation process.

EQUIPMENT FOR INDUSTRIAL USE

Equipment designed and manufactured for industrial use and at a very competitive price.