Disease Detection with Arduino PLC in a Fry Hatchery

Ensure the security and quality in your installations

Disease Detection with Arduino PLC in a Fry Hatchery

Ensure the security and quality in your installations

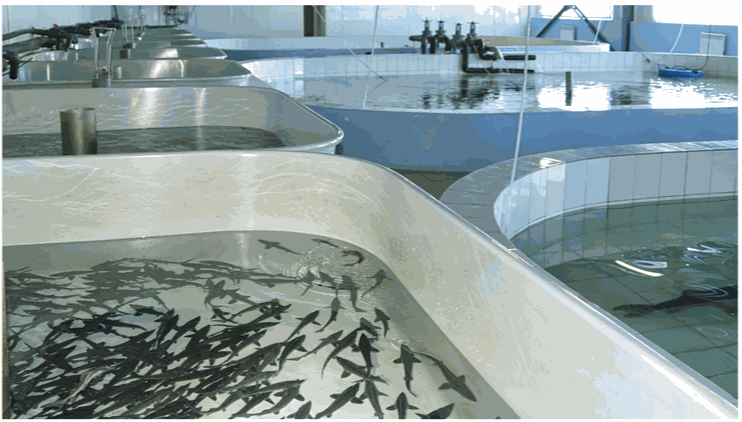

The purpose of a fry hatchery is to produce high quality fish for subsequent sale, so it is important to maintain constant control of the environment and the living conditions of the breeding stock to ensure their welfare, health and optimal growth, complying with quality and animal welfare standards.

GOAL OF THE SOLUTION

The aim of automating this fry disease detection process is to reduce human error through the installation of Programmable Logic Controllers (PLCs) in a monitoring system to prevent future disease caused by factors such as:

Temperature

Sudden changes or extreme temperatures can stress fry and increase their susceptibility to disease. It is important to maintain a constant and appropriate water temperature to ensure their well-being.

Water quality

Water should have a suitable chemical composition and be free of contaminants to maintain fish health. Regular monitoring helps to detect any problems to prevent the onset of disease.

Feeding

Fry must receive an adequate and balanced diet that provides the nutrients necessary to maintain their health and well-being. An inadequate diet weakens their immune system, making them more susceptible to disease.

Lighting

Changes in light and dark cycles can alter circadian rhythms affecting fry behaviour and metabolism. It is important to maintain an adequate and regular light cycle to ensure welfare.

IMPLEMENTATION OF THE ARDUINO PLC

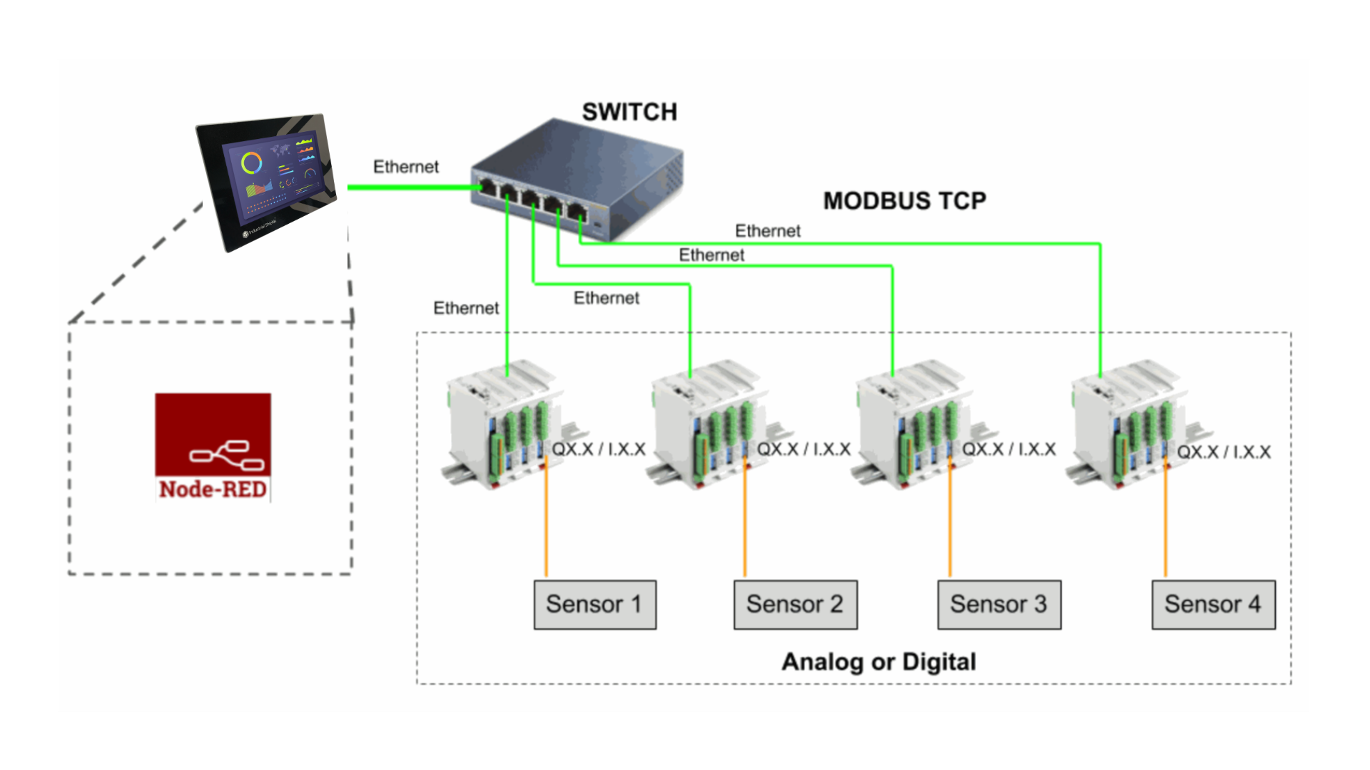

Initially, Industrial Shields PLCs were configured to be able to identify critical process variables such as temperature, salinity, pH, oxygen level and fish behavior, which can indicate the presence of disease. This data is sent to a centralised system for analysis and control.

A server is installed to store and process the data collected by the automation system, in addition to:

- Computers and software to program and configure the PLCs and other system components;

- Cameras and digital sensors connected to measure these critical variables and monitor the behavior of fish.

The data is sent to the PLCs on an ongoing basis so that they can analyse and process the data to detect changes in the critical variables.

PLCs use a combination of algorithms and Boolean logic to determine when alerts will be triggered and sent to hatchery operators via visual signals.

The industrial PLCs will determine the response actions to be taken once alerts are triggered, and alongside that, an automatic dosing system will be implemented to administer medicines with precision and control.

This system will enable various actions to be taken, including but not limited to halting the feed supply, adjusting the water temperature or salinity, or administering medication to fry.

BENEFITS OF THE MONITORING SYSTEM WITH ARDUINO PLC

Improved accuracy

Automation reduces the risk of human error in testing and analysis, which increases the accuracy of disease detection in fry.

This allows early diagnosis of diseases and rapid implementation of preventive measures to avoid their spread.

Time savings

By automating the process, tests and analyses can be performed in a much shorter time than if they were done manually.

This means that test results will be available much more quickly, enabling a faster response to disease outbreaks.

¿WHY INDUSTRIAL SHIELDS?

Industrial Shields won the project and beat its main competitors on the following points:

OPEN SOLUTION

No licence fees.

MODULAR SOLUTION

Product specifications can be expanded in the future.

TECHNICAL SUPORT

Our support team is dedicated before, during and after the sales and installation process.

EQUIPMENT FOR INDUSTRIAL USE

Equipment designed and manufactured for industrial use and priced lower than competitive products.