In an effort to resolve difficulties, enhance procedures, and uncover economies, manufacturers are unceasingly striving.

Technology

- Connectivity

- Automation improvements

1. 2020-2030: the ongoing decade of smart factories

In 2024, the widespread adoption of smart factories is expected to reach a turning point, shifting from isolated usage of smart technology to extensive deployment of interconnected systems that fully leverage the advantages of data analysis and inter-machine communication. This is due to several factors, including:

The replacement of older machinery with new machines equipped with integrated monitoring tools and sensors

The pressure to stay competitive with peers who have already adopted smart technology

The declining costs

Increasingly apparent benefits of smart factory software and equipment, such as more efficient maintenance, improved process visibility, and reduced operating expenses.

2. From Green Energy to Sustainable Supply Chains: A Focus on Carbon Neutrality

Environmental, social, and governance (ESG) issues are becoming more of a concern for manufacturers, which will increase the importance of sustainable practices and the pursuit of carbon-neutral methods.

Manufacturers may anticipate seeing increased ESG criteria from commercial customers in addition to sustainability requirements for contracts with government, municipal, and institutional clients.

3. Reinventing the Supply Chain: Reassessment in the Age of Digitalization

Manufacturers can use data to more quickly adjust to the supply chain interruptions brought on by COVID and try to reduce their unpredictable nature.

4. The importance of reshoring

Reshoring was frequently touted as an industry goal before the COVID pandemic, showing a renewed emphasis on quality, service, and quick fulfillment. In 2020 and 2021, the significance of conducting business locally was brought into stark view, and reshoring started to become more than just a trendy term.

Reshoring will become established as a more practical and essential supply chain option in 2022, moving beyond a quick fix to a more standard mode of operation.

5. Employee safety and health

Employee safety has always been a top priority, and is less typically seen as a "trend" than as something that should be promoted daily. Like everything else, COVID-19 changed that, and new methods of keeping an eye on and maintaining employee health are crucial for both your workforce and your company.

Precautionary protocols will at the very least continue throughout the year, with some facilities opting to use more sophisticated equipment to track employee movements, locations, and even temperatures.

6. Smarter Maintenance for Bigger Margins: The Role of Data Analytics

For the past few years, trends lists have included:

Sensors

Remote monitoring

- Connected devices

- The Internet of Things (IOT)

and this year is no exception.

Why? On the one hand, manufacturers are innovating more successful ways to use data to drive predictive maintenance as sensors continue to become more widespread, communications are even faster and more dependable, etc. Given the financial hardship that many facilities experienced in 2020 and 2021 and may continue to experience in 2022, more effective, efficient maintenance is essential.

7. Leveraging Virtual Processes for Global Business Success

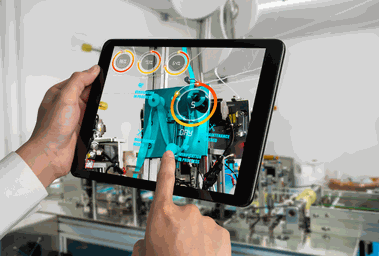

By enabling remote monitoring, servicing, and equipment operation — all without the need to be on-site — technologies like:

Digital twins

- Machine learning

- AI (artificial intelligence)

- AR (augmented reality)

- VR (and virtual reality)

are assisting manufacturers in navigating COVID challenges.

Virtual and remote operation is consistent with other recent trends in the manufacturing process that enable access, flexibility, and safety, with communication moving closer to real-time and the computing power to truly make it seem like the operator is in the room with the machine.

8. The Art of Balancing Demand and Resources

Companies need to be more effective and nimble than ever in managing the skills gap and labor shortages due to the reality of the epidemic and current changes in the manufacturing sector.

Manufacturers are losing money if they are unable to increase capacity and throughput in order to meet the growing demand for manufactured goods. This calls for a:

Thorough analysis of all procedures

- Identifying ways to boost productivity

- Assist the workforce

while bridging the skills gap and offering state-of-the-art technical training to match current demands.

Some of these patterns are extensions of ones you may be familiar with from previous years, while others are new as a result of the particular circumstances of the present.

The Future of Manufacturing: 8 Trends to Keep an Eye On