One of the big steps, or in many cases, the final step, is when from a prototype, to which elements have been added and removed, adjusting parameters, defining uses, etc. in its prototyping phase, we finally move to a solution like a machine or production line.

Regardless of the sector to which it is directed, that machine, equipment, line, will need controls, automatisms, sensorization, monitoring, etc.

There are still many types of tools or machines in use, and not only in museums, which, despite being not old but ancient, fulfil their function. These are machines where manual intervention is almost total. As the vast majority of companies and/or sectors must be competitive if they want to remain on the market, this kind of machines have been and are being replaced by semi-automatic or automatic solutions and even integrated within increasingly sophisticated production processes.

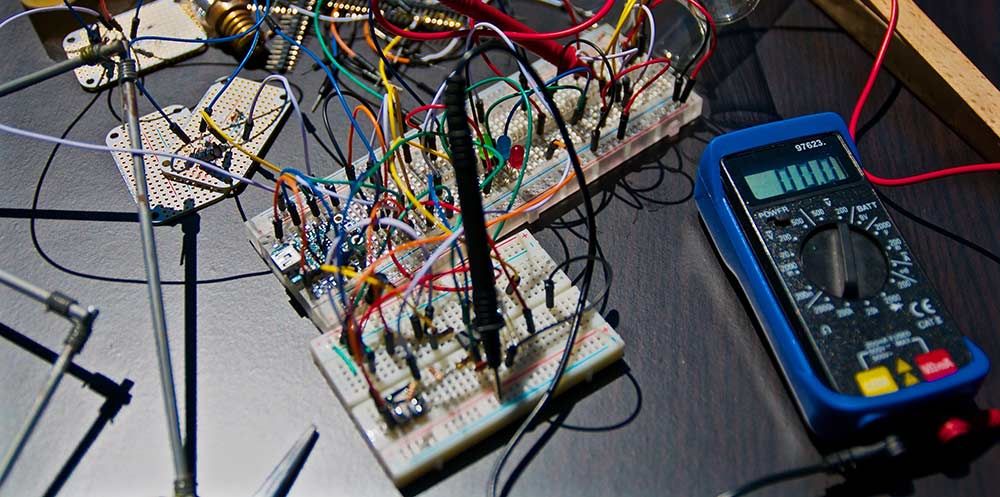

The evolution has always been accompanied by many hours of trial and error, testing, prototypes... Fortunately, in the times we are living with 3D printers, the low cost of electrical, mechanical or electronic components and the use of microcontrollers or microprocessors with very low costs, R & D processes prior to development and final manufacturing have been accelerated and made very affordable.

A key part in both the development and production of machinery is its control and the technology/methodology used to do so. Sometimes, at the least, we can talk about a machine that is not going to need integration within a production line, or monitoring elements for an optimization of the processes it performs. But in most solutions, one or more of these elements will be required:

automation

semi-automation

on-machine control

control from central/control room

remote control and/or wireless

monitoring (machine, local, fog, cloud)

and as many integrations as necessary, both at the startup and during the life of the solution.

Some shocking things have been made with Arduino or Raspberry Pi boards, we have witnessed some of them; the whole maker community can prove it: from the ArduSat satellite to hundreds of gadgets such as robots or drones.

So, are we talking about machines or gadgets?

We are talking about control, about programming a machine so that it can be controlled, monitored and automated using a free hardware board.

Few machines can be controlled by a board that is not designed and manufactured for this purpose, but they can be controlled by our PLCs based on Open Source Hardware, certified and prepared for the demanding industrial environment.

Why change your programming between the prototype phase and the production phase?

If in the prototype phase you program in Arduino when you have the machine ready, you can continue programming in Arduino, the only thing is that it will be inside an Industrial PLC, but based on Open Source Hardware.

When going from prototype to solution means going from Arduino to Arduino