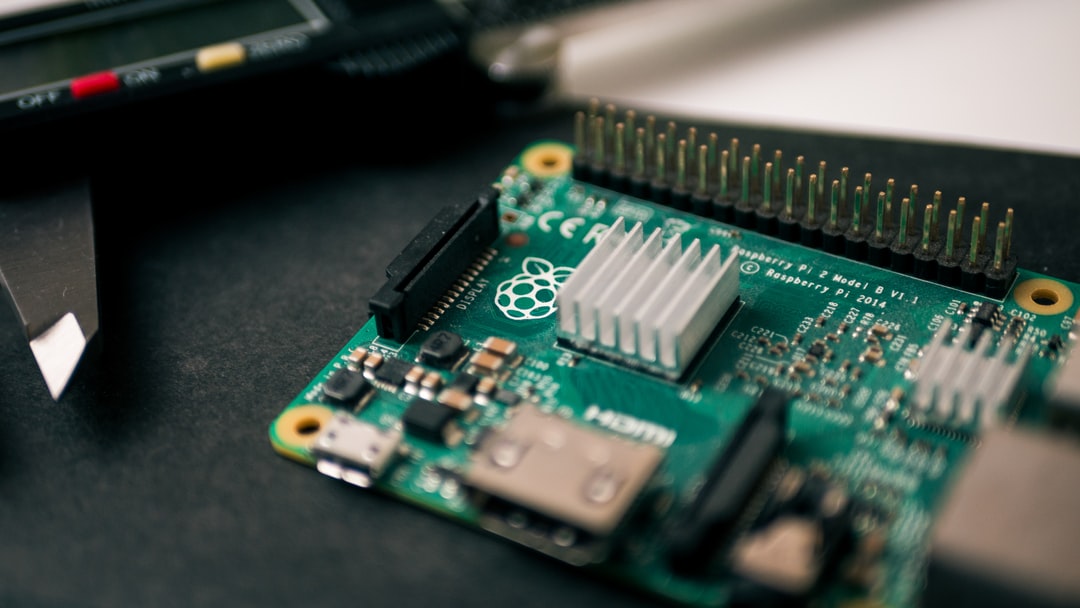

The current situation is complicated, both socially and economically. Apart from the damage caused by the COVID-19 pandemic, the global crisis of component shortages is affecting millions of companies around the world.

Here are some of the possible causes of the lack of chips and components, and the consequences that this situation may have.

What are the causes of chip storage?

First of all, we must go back to the Huawei crisis. In 2018, the United States accused the Chinese company of espionage and cyber espionage. According to the US, Huawei used its infrastructure and information technology to access industrial secrets, user data, and other confidential information from several countries, and disclosed them to the Chinese government.

This conflict had some far-reaching repercussions. The main one came at the end of 2018, when Meng Wanzhou —Huawei's CEO and heiress— was arrested in Vancouver, Canada, on charges of alleged fraud, conspiracy and embezzlement. This incident led to US companies such as Google and Apple being forced to stop dealing with Huawei, with the economic loss that this entailed.

This whole situation generated by the US government sowed panic in Asian companies, which have been accumulating a larger stock than normal, producing an imbalance in the production system.

On the second hand, COVID-19 has led to poor planning. At the onset of the pandemic, many companies, especially automotive companies, cancelled their chip orders because they thought the economy would suffer a prolonged downturn.

Thus, automotive chip manufacturers shifted their production to meet the excessive demand for chips for the consumer products most used in households during the pandemic: computers, toys, tablets, etc.

In addition, many original equipment manufacturers (i.e. those who build systems or components for another company's end products) closed down due to the pandemic, and their suppliers had to look for other markets.

As for the large cloud service providers, their demand skyrocketed with the pandemic and teleworking. Companies such as AWS, Microsoft Azure, Alibaba, etc., buy a lot of semiconductors and their demand continues to grow, which means an increase in demand for chips and electronic components.

Last but not least, bad luck also comes into play.

In March 2021, the ship 'Ever Given' of the Taiwanese company Evergreen, ran aground in the Suez Canal due to a sandstorm. By blocking more than a hundred ships with hundreds of containers each, the goods did not reach their destinations in time, which also disrupted the supply chain.

In addition, in June 2021, a coronavirus outbreak in southern China clogged critical ports for global trade. In Guangdong (home to some of the world's busiest container ports and handling tens of thousands of containers a day), flights were cancelled, communities were blocked and trade was suspended along its coastline, to control the rise in COVID cases as several positives were found in its dockworkers. This situation also spread to ports such as Shekou, Chiwan and Nansha, which are the fourth and fifth largest container ports in the world.

Finally, the fact that cryptocurrencies are on the rise could also influence the shortage of chips, as miners seeking to obtain them use cryptocurrency farms, as well as graphics cards and computer chips.

What are the effects of the chip shortage?

Undoubtedly, the automotive and industrial sectors are the hardest hit by the chip shortage. As two non-priority sectors, the shortages affect them in the following way:

The lack of components and the increased cost of some raw materials leads to an increase in the value of new products, as well as an increase in the residual value of used products.

Some products will not be shipped or will be delayed. Component lead times have increased and the time to ship the final product to end customers or distributors is longer.

Decrease in market value. Being able to ship fewer products accumulates significant rates of decline in terms of sales.

When will the global chip shortage end?

If one thing is certain, it is that demand for chips is increasing, and it is costly to meet this demand because supply is currently tight.

As for the end of the shortage, analysts' and investors' opinions are mixed. While some believe that this shortage may end by mid-2022, others think that this crisis will last for a long time, until 2023, as many factors come into play.

So, if this is the case, we will just have to be patient.

2021 Global Chip Shortage