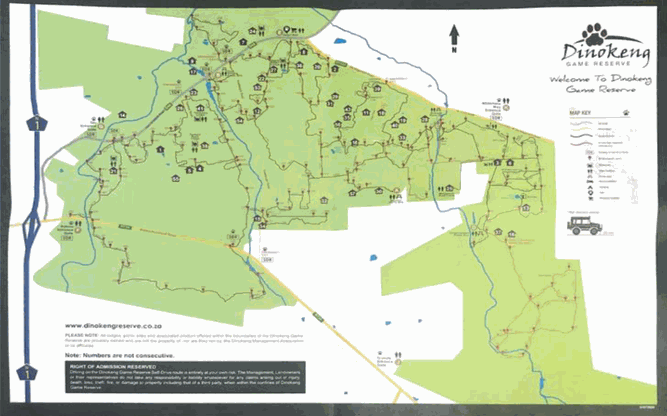

Dinokeng Game Reserve:

Improving Access Control

+ Savings on consumables

+ Better control

+ Improved security

+ More reliable system

Situation

Is the access system working as expected?

Access control to nature reserves is becoming more and more frequent.

On the one hand, it is important to maintain the security of the habitat and the animals that inhabit it. On the other hand, it is also essential to guarantee access and control for the professionals working in the park, as well as for visitors.

The current access system was obsolete and it was decided to modernise the facility to provide it with greater security, better control, and more autonomy in automatic processes.

It is also important to note the high maintenance costs of the current installation.

Upgrading of the current outdated wire based RS485 interface access control system at 5 entrance gates to the game reserve.

Maintenance cost and parts availability on the existing system have become prohibitive.

Challenge

Creating a wireless network, a better technology, and a secure and reliable installation.

Creating a wireless network, a better technology, and a secure and reliable installation.

There were different points to take into account when solving the customer's requirements:

- The use of Wi-Fi based technology in a centralised control system should allow gate access through barcoded and QR Coded tickets issued via a ‘No Touch’ sensor at gate entrances.

- TSP700II slip printers had to be Wi-Fi enabled, with the use of Serial to Wi-Fi devices to allow reuse of existing working equipment.

- Upon a hand wave near the ‘No Touch’ sensor at the entrance gate, a microcontroller should communicate with the controller software of the gate to enable a ticket to be printed and a barrier to be opened. There can be up to 2 ‘No Touch’ sensors for normal and large vehicles.

The Gañar Group company was requested to upgrade the Gate Access Control at Dinokeng Game Reserve.

The goal was to control the system with open source technology. So, by means of a PLC with Wi-Fi and a sensor, Gañar Group succeeded in enabling the printing of the ticket and opening a barrier with quality technology and easy programming.

Implementation

An easy start with a prototype to evaluate the functionality

The project started with ESP32 microchips and got a basic system up and running within 3 months.

The challenge was to get a stable and reliable local area Wi-Fi network, to which all the Serial Wi-Fi device, both the printers and barcode scanners, had to be connected.

Then, to set up these devices to communicate via socket connections to the gate controller software computer’s IP address on specific ports.

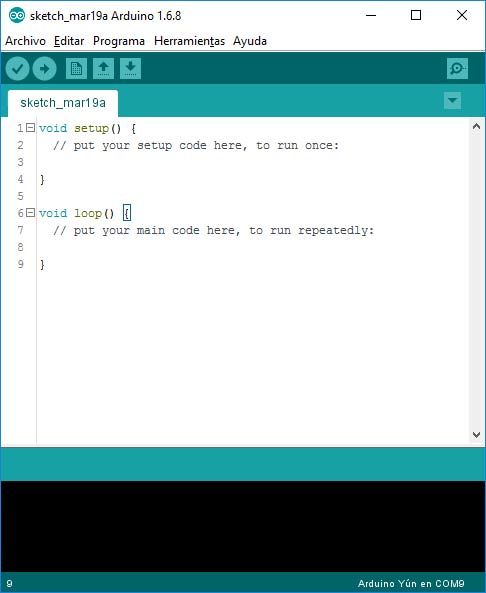

For the ESP32, the HTTP protocol using port 80 locally was employed. The latter code had to be written in the Arduino IDE environment to set up a local web server and save the parameter settings on the ESP’s flash memory.

The microprocessor had to be written in Access Point (AP) mode, so that it could be accessed by Wi-Fi device: smartphone, tablet or Wi-Fi enabled computer.

Electromagnetic disturbances interfered with the ESP32 microcontrollers, causing hang-ups and disconnects.

Solving important issues

How to get rid of the electromagnetic interference?

At this stage, it was necessary to use the ESP32 PLC 19R device on both, the entrance and exit gates, in the hope of eliminating electromagnetic interference using and industrial controller.

Customer saved up to 80% on slip printer type tickets, as well as on rack hardware components.

The project is currently running 24/7 with minimal maintenance.

At the entrance gates, Wi-Fi enabled 1D/2D barcode readers should allow prepaid permits to be scanned and open the barrier upon verification of payment via a cloud-based database.

The relevant database could also be a third-party institution that is allowed to sell permits. The barcode scanners send barcodes to the gate controller software, from where the validity checks are executed.

Barcodes are linked to an Entrance timestamp that should also be able to operate off-line in case no internet connection is available.

This timestamp will be used upon exit to determine the lenght of stay in the park.

Exit barcode scanners are required at exit gates to determine the paid or free status of a ticket and communicate directly via Wi-Fi to the gate controller software.

The software will then validate the barcode in the cloud database and send messages to the ESP32 PLC 19R, which in turn should display it on a connected 2-line LCD display to inform the visitor.

The message determines whether an open gate command is executed or not.

Expectations exceeded

Both the entrance and exit gate ESP32 software was adapted to accommodate the new board types and model, all done within the Arduino IDE. The expectations of the performance of these devices were exceeded. Especially, the shielding aspect was a vast improvement.

The addition of an external antenna typically improved the Received Signal Strength Indicator (RSSI) from -80dB to- 50dB.

Advantages

Less is More

With a single Wi-Fi PLC, it is possible to remotely manage the entire solution and all the control system. Reducing the hardware of the Gate Access Control installation makes it easy, fast, and cheap.

Focus on customer

One of the most important demands of the solution was the need for automatic control.

Thanks to the Wi-Fi PLC, this can be done.

.jpg)

Easy programming

This ESP32 PLC can be programmed with the system that best suits the customer's needs. It is an open source based programming, making it easy for the customer.

Why Industrial Shields?

Industrial Shields won the project and beat its main competitors thanks to these main factors:

Open Solution

No license fees

Modular solution

Product specifications can be extended in the future.

Technical support

Our team is available to solve your questions and issues.

Lower and afforable price

Equipment for industrial use at a competitive price.